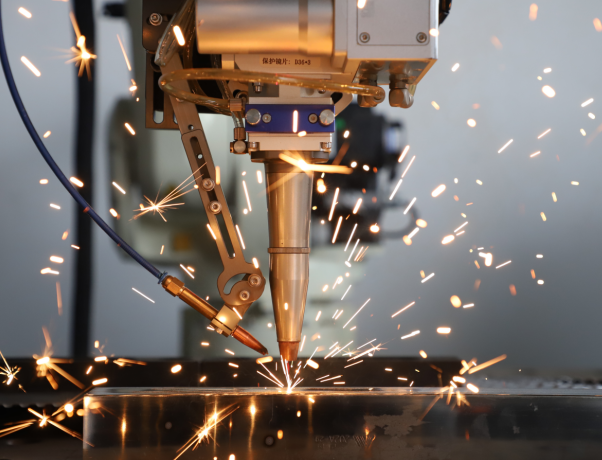

XT Laser-metal laser cutting machine

In the 21st century, China’s stainless steel industry has developed rapidly. From 2000 to 2006, the annual growth rate of stainless steel consumption in China was above 21.17%. Among them, in 2001, China’s apparent consumption of stainless steel reached 2.05 million tons, surpassing the United States as the world’s largest consumer of stainless steel.

In practical applications, steel resistant to weak corrosion medium is often called stainless steel, and steel resistant to chemical medium corrosion is called acid-resistant steel. Stainless steel is one of the metal materials. The laser equipment used for this series of materials is called stainless steel laser cutting machine. Just like the sheet steel laser cutting machine belongs to the metal laser cutting machine, there are also carbon steel laser cutting machine, aluminum plate laser cutting machine, steel plate laser cutting machine, etc.

Stainless steel laser cutting machine is a classification of metal laser cutting machines. Stainless steel has a wide range of applications, such as kitchen equipment, general stretch materials, gas stoves, refrigerators, electrical appliances, washing machines, dryers, microwave ovens, electronic components, steel tubes, decorative tubes, structural tubes, pipe rows, building materials, regrinding, elevators, interior and exterior decoration materials, windows, doors, chemical equipment, heat exchangers, boilers, tanks, etc, It can be seen that stainless steel is widely used. However, the stainless steel laser cutting machine requires a high level of surface smoothness for these stainless steel products. What should be done to deal with burrs when the stainless steel laser cutting machine is cutting.

When cutting with stainless steel laser cutting machine, burr is usually caused by the cutting nozzle of the cutting head. This factor should be investigated first. If the problem cannot be solved by replacing the cutting nozzle, check whether the guide rail of the laser cutting machine moves smoothly. The big problem can solve the burr problem when the stainless steel laser cutting machine cuts the product.

Laser cutting machine for stainless steel sheet also occupies a large proportion in industrial production. The main difference between stainless steel and low carbon copper lies in its different composition and cutting mechanism. Stainless steel containing 1% to 20% chromium is easy to destroy the oxidation process. During cutting, iron in stainless steel will react exothermically with oxygen, while chromium oxidation has the characteristics of preventing oxygen from entering the molten material, reducing the amount of oxygen entering the molten layer, incomplete oxidation of the molten layer, and reduced reaction.

Compared with low carbon steel, stainless steel cutting requires higher laser power and oxygen pressure. Although stainless steel cutting can achieve satisfactory cutting effect, it is difficult to obtain a completely viscous slag-free cut. Cutting stainless steel with inert gas as auxiliary gas can obtain non-oxidation cutting edge, which can be directly used for welding, but its cutting speed is about 10% lower than that of oxygen as auxiliary gas.

The most important process parameters that affect the cutting quality of stainless steel are cutting speed, laser power, oxygen partial pressure and focus, which respectively represent the impact of laser power, cutting speed and oxygen partial pressure on the cutting quality of 2mm thick stainless steel.