3D printing of nanoparticles is attracting increasing attention due to its wide range of applications. Now, Md Shah Alam and co-workers from the University of Dayton in the USA have demonstrated a laser-based opto-thermomechanical nanoprinting (OTM-NP) method that not only has sub-100 nm accuracy but also features error correction of the printing (Nano Lett. https://doi.org/10.1021/acs.nanolett.0c01261; 2020).

Credit: American Chemical Society

The OTM-NP technique makes use of a donor substrate (polydimethylsiloxane on a glass coverslip) that holds a metallic (Au) nanoparticle via the van der Waals force and a receiver substrate. The gap between the donor and the receiver substrates is typically 1 μm. A continuous-wave laser operating at 1,064 nm wavelength is focused onto the Au nanoparticle with a beam intensity of 100 mW μm–2.

The Au nanoparticle absorbs the laser energy and heats the donor substrate beneath it, leading to rapid thermal expansion. Owing to this expansion force, the Au nanoparticle is released from the donor substrate and moves towards the receiver substrate, guided by the optical gradient and axial forces of the focused laser beam. When the Au nanoparticle reaches the receiver substrate, it is held in place by the van der Waals force. A printing accuracy of better than 99 nm was reported.

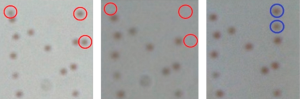

Printing error correction can be implemented by using the nanoparticle additive and removal capabilities of OTM-NP. As an example, the letter ‘N’, composed of a pattern of fourteen 200-nm-sized Au nanoparticles, was printed on an indium tin oxide-coated glass substrate. To repair the pattern ‘N’ and correct for any positional errors of the nanoparticles, three Au nanoparticles (marked in the red circles in the left picture) were selectively removed from the letter (in the middle picture). Then, two new Au nanoparticles (marked in the blue circles in the right picture) were added to the letter ‘N’ to repair the structure. Both the nanoprinting and the nanorepairing can be conducted on the same platform under ambient conditions.

As for applications, the researchers say that the OTM-NP technique could prove useful for fabricating structures such as 2D metasurfaces and 3D metamaterials.