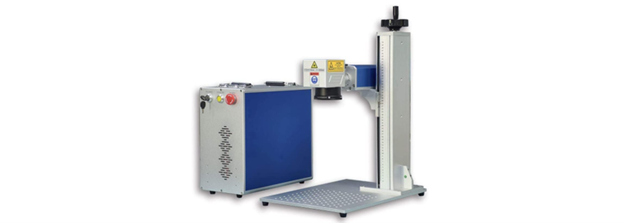

Common Laser Marking Machines Component

There are different laser machines, each with unique features and applications. As a result, they have different components. However, the common components in all laser marking machines are below.

· Component #1: Laser Generator

The laser generator is responsible for generating the laser beam; hence it is the core of how a laser marking machine works. It is the engine of any laser marking machine and the most expensive component on the list.

The laser generator is responsible for generating the laser beam; hence it is the core of how a laser marking machine works. It is the engine of any laser marking machine and the most expensive component on the list.

Laser generators are majorly fiber or CO2 lasers. However, other types differ in their features, such as YAG lasers. Furthermore, many brands include JPT, IPG, Max, and Raycus. Each one has its uniqueness. For example, JPT laser sources works based on the MOPA technology, are compatible with many materials and have high flexibility.

· Component #2: Laser head

The laser head comprises the nozzle, focus lens such as the f-theta lens, focus tracking system, etc. The laser head depends on the device, with some having a handheld movable laser head and being responsible for determining the marking speed and the fineness of the output laser line.

The laser head comprises the nozzle, focus lens such as the f-theta lens, focus tracking system, etc. The laser head depends on the device, with some having a handheld movable laser head and being responsible for determining the marking speed and the fineness of the output laser line.

· Component #3: Software/Display

The marking software is the machine’s brain, responsible for controlling the marking operation. Currently, there is much software for laser marking machines. For example, some laser markers have independently developed software while others use conventional software such as EzCAD. Each software has a display unit through which the machine is controlled. Ensure the display unit is devoid of liquids and cleaned with dry, clean, and soft cloth.

· Component #4: Water Chiller

The water chiller is an important component of every laser marker that functions in cooling the machine. Laser marking machines generate heat, and the chiller can quickly and efficiently cool the laser source, laser head, and other devices. Ensure the chiller you get has input and output control device switches, stable performance, and advanced functions for cooling water flow

· Component #5: Fume Extractor

Laser markers generate fumes during the marking process and are removed from the marking scene by the fume extractor. These components are peculiar to CO2 laser engravers and help absorb and purify the harmful gases produced by the process.

Laser markers generate fumes during the marking process and are removed from the marking scene by the fume extractor. These components are peculiar to CO2 laser engravers and help absorb and purify the harmful gases produced by the process.