— 12KW VS 20KW Performance Competition–

With the pursuit of efficiency and craftsmanship in the entire processing and manufacturing industry, domestic laser cutting technology has continuously made breakthroughs. 10KW laser cutting machines are enthusiastically sought after by the entire industry due to their unique advantages such as high power, high efficiency, and high stability. The era of the 10,000-watt laser cutting machine has come, owning the 10,000-watt laser cutting machine will lead the future.

High-power large-format fiber laser cutting machine has the advantages of large cutting format and fast cutting speed. It can cut thicker metal sheets and has stable performance. It is an inevitable trend in the development of laser cutting technology. With the continuous improvement of market demand, the in-depth application of laser cutting technology will further promote the development of laser cutting machines to high precision and high power.

At present, the most popular laser cutting power in the market is 10,000 watts, and the most popular among 10,000 watts is the 12KW laser cutting machine, which occupies a large market share by virtue of its excellent performance and price advantages. With the significant advantages of the 10,000W series, the market has begun to develop towards higher power, starting from 12KW to 20KW or even 30KW, trying to realize more possibilities. Create a whirlwind. Everyone can’t help but start thinking, the higher the power, the better? Which power is the most cost-effective? Which one is more suitable? You may have many questions about these. In fact, for different users, because each company has different processing materials, different product requirements, and production needs are also different, so the most important thing is to choose the one that suits you. The higher the better. So how to choose the most suitable power for you, let’s focus on comparing the cutting efficiency of 12KW and 20KW, hoping to help you choose.

12KW VS 20KW cutting performance comparison

When purchasing a fiber laser cutting machine, you need to consider whether the power of the equipment can meet your own cutting needs. The power of the laser cutting machine is one of the core parameters of the equipment. Fiber laser cutting machine cuts metal materials, mainly stainless steel, carbon steel, aluminum plate, brass, etc. The higher the power of the equipment, the thicker the cutting thickness and the faster the cutting speed.

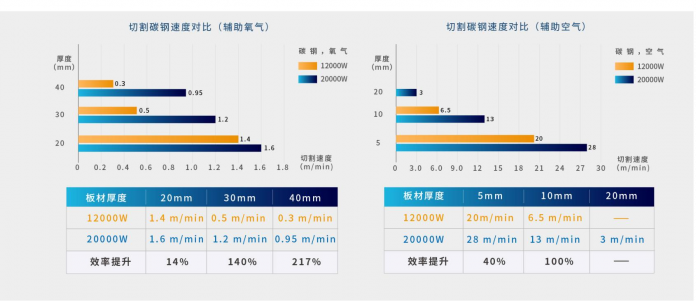

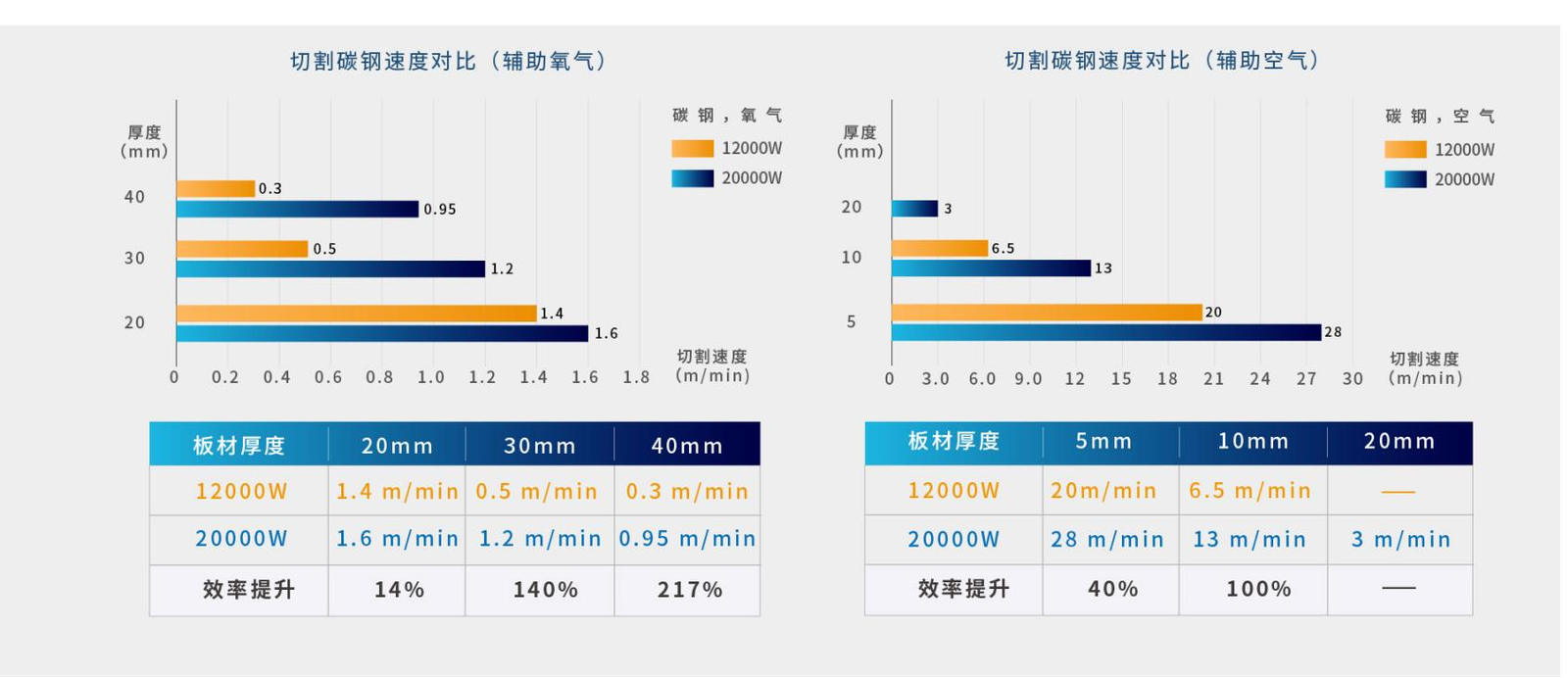

Under auxiliary oxygen conditions, when cutting 30mm and 40mm carbon steel, the 20KW laser cutting machine has obvious advantages, and the cutting efficiency is about 1.5 times and 2 times higher than that of the 12KW laser cutting machine.

Under the condition of auxiliary air, when cutting 10mm carbon steel, the laser cutting efficiency of 20KW is double that of 12KW; 12KW cannot cut 20mm carbon steel. According to the market test, in addition to saving time and labor costs for cutting 20mm carbon steel, the gas cost of air cutting is about 5 yuan/hour less than that of oxygen cutting.

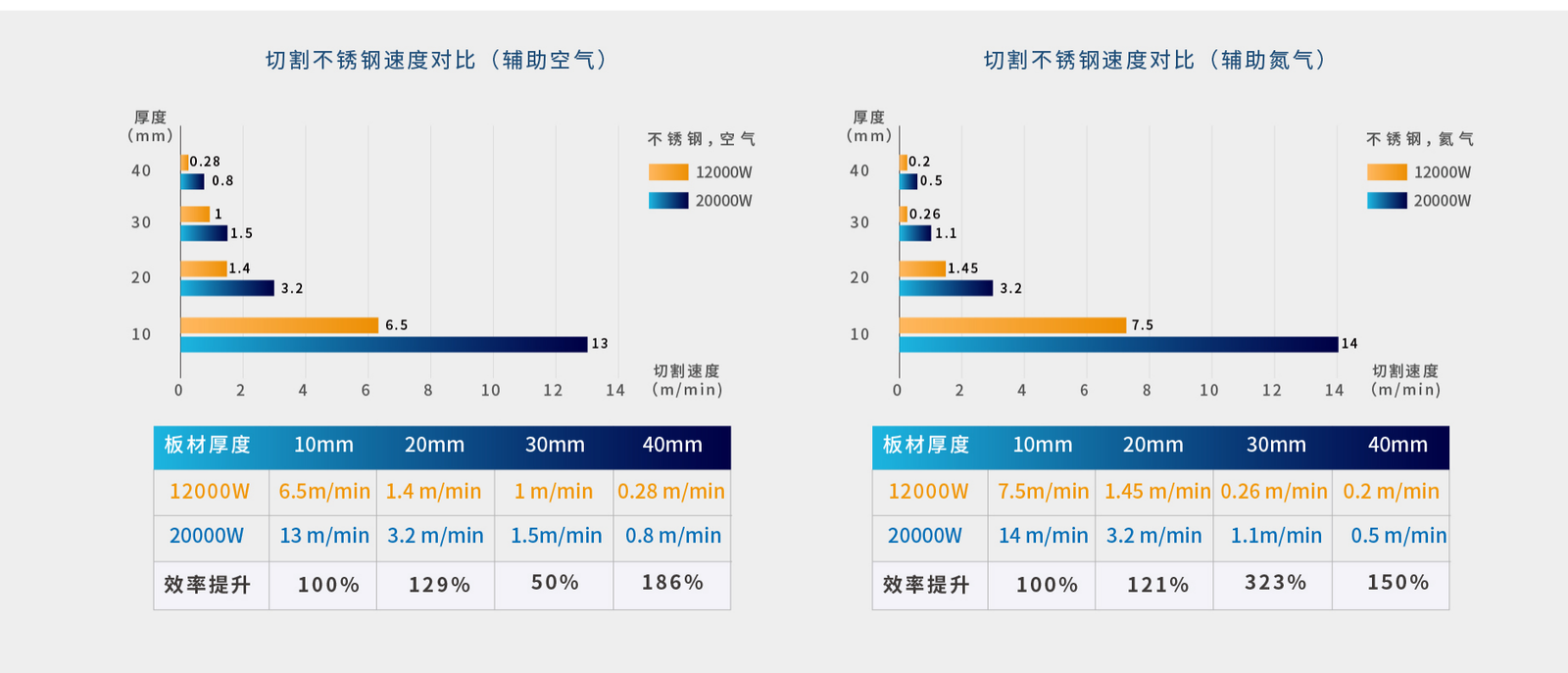

20kW vs 12kW stainless steel cutting speed comparison (for reference only)

When cutting stainless steel, whether it is auxiliary air or nitrogen, the overall advantage of the 20KW laser cutting machine is very obvious. The cutting efficiency is greatly improved compared with 12KW, and most of the cutting efficiency of 10mm-40mm stainless steel is more than doubled.

From the comparison in the figure, we can see that the cutting thickness and speed of the 20KW cutting machine are relatively better than the 12KW cutting machine in terms of different materials. The majority of users and friends can choose the suitable one according to the thickness and material of the processed plate. Its own cutting machine, the two cutting machines are currently the mainstream metal processing products in the market.

The main industry application of laser cutting machine

At present, laser cutting machines are mainly used in sheet metal processing, hardware products, kitchen utensils, machinery manufacturing, aerospace, auto parts manufacturing, communication equipment, steel structures and other related manufacturing and processing industries to meet the needs of different users for fiber laser cutting machines. demand. Different industries, different products, and different processing requirements have different power requirements.

According to market research:

Small fiber laser cutting machines are mainly used in hardware, kitchen and kitchen utensils and other industries;

Medium power fiber laser cutting machines are mainly used in advertising, sheet metal processing, fitness equipment, chassis and other industries;

High-power fiber laser cutting machines are mainly used in aerospace, rail transit, auto parts manufacturing, communication equipment, high-end mechanical equipment manufacturing and other industries;

In general, the choice of high power fiber laser cutting machine depends on the cutting needs of customers.

After comparison, everyone has a preliminary understanding of 12KW and 20KW laser cutting machine products. In fact, no matter how much power, the suitable one is the best. When purchasing a fiber laser cutting machine, you can compare and choose from multiple directions such as processing details, thickness, speed, price, after-sales service, etc., and match the corresponding power level according to the material to be processed. At the same time, don’t forget to check whether the price meets you. budget.

XT 10KW LASER

While looking at the product data, we also need to look at the brand strength. Let’s take a look at the 10,000-watt laser products of XT LASER, which has 18 years of experience in laser manufacturing, R&D and production:

XT LASER 6000W-30000W Laser Cutting Machine

XT LASER has invested a lot of research and development and labor costs, and is striding forward towards high-power products. At present, its self-developed and produced 6000W-30000W laser cutting machines occupy a place in the domestic and foreign markets, and the repurchase rate of old customers is extremely high. The 10,000-watt-class cutting machine under XT LASER has open type and fully enclosed type, which can cut various materials such as plates and pipes, and can also be customized according to customer needs to meet all production needs of customers.

At present, XT LASER has undertaken the design, development and project implementation of more than 20,000 sets of laser equipment around the world. The high-power 10,000-watt cutting machine has covered key areas of the world, more than 30 provinces and cities such as Guangzhou, Hebei, Shandong, and Liaoning in China, and South America internationally. More than 160 countries and regions including North America, Northern Europe and the Middle East have regional model projects. From product quality to full life cycle services for customers and products, it is recognized by customers around the world.