Plate cutting+tube cutting

All rounders live online

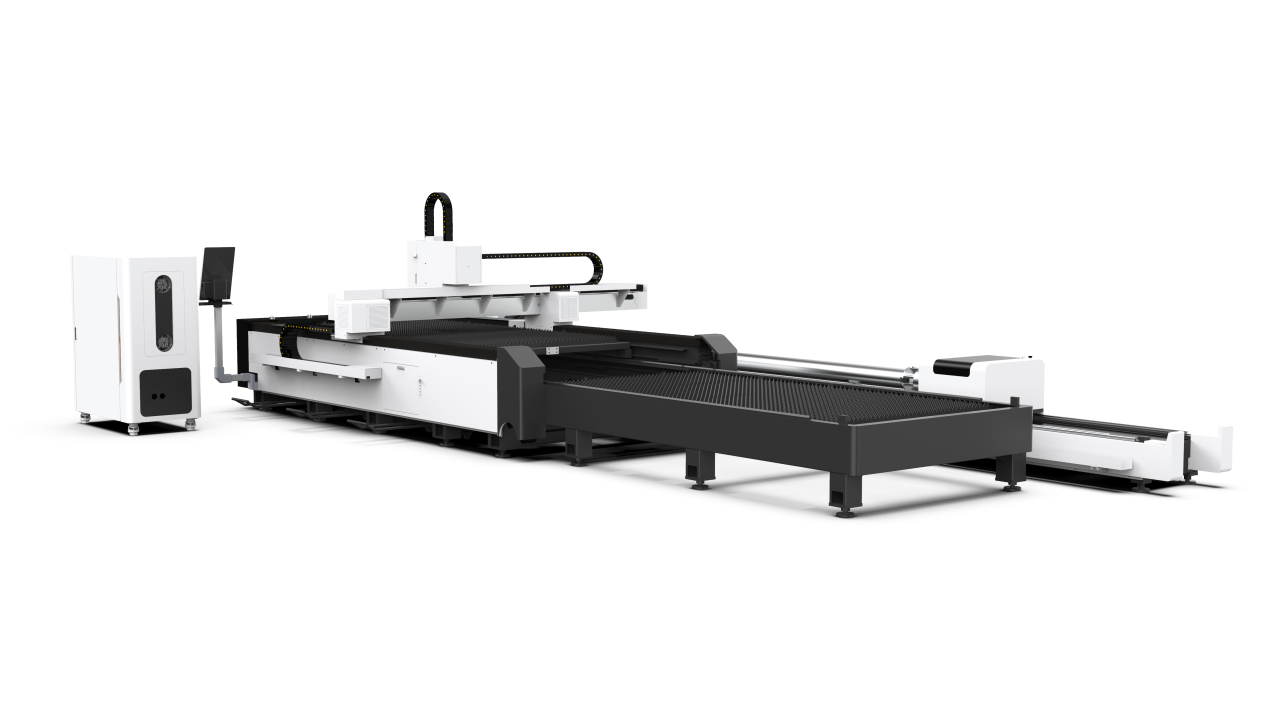

XT Laser Open Exchange Platform Plate and Tube Integrated Machine

Efficient and time-saving flight cutting

Flexible switching of plate and tube cutting

One click centering and precise clamping

Stable operation without deformation

CNC intelligent operation with ease

Save space and save costs

Dual pneumatic chuck flexible and efficient

Advanced chuck clamping system

Accurate control of speed and clamping force

Adopting 2 rows of rollers and 6m pipe double support brackets

Claw clamping speed is fast

The pipe material does not deform or fall off

Cutting accuracy without deviation

Ultra light aluminum beam brings higher load capacity

Adopting ultra-light aluminum crossbeam

Significantly reduce sports driving load

High strength inner cavity design effectively disperses internal and external stresses

Anti twisting and anti overturning, with better mechanical properties

Significantly increase the rigidity of the gantry crossbeam

High speed, high precision, and fast response

Simple and smooth human-machine cooperation

Intelligent high-definition display screen

Professional intelligent CNC system

One click start automatic cutting

Real time mastery of operational content

Rich process database

Easy to handle batch processing

High rigidity and overweight plate welded bed

After stress annealing and natural aging treatment

High mechanical strength, not easily deformed

Bed weight, low machine vibration, and good seismic resistance

Ensure improved cutting accuracy

Stable, sturdy, and durable

Product parameters

The saying goes, “If you want to do something well, you must first use your tools.” In order to continuously improve product process details and gain competitive advantages in equipment, the XT Laser Open Exchange Plate and Tube Integrated Cutting Machine combines multiple cutting technologies, and can achieve the cutting of various profiles such as rectangular tubes, square tubes, round tubes, elliptical tubes, angle steels, and groove steels in one machine. Suitable for cutting various metals such as carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, copper, etc. One equipment can meet the dual needs of cutting plates and pipes, saving costs and space.

Accumulating thickness, becoming a tool, moving steadily, and achieving great success

1530/2040/2060/2560 Multiple machining ranges supported

Outline square tubes, circular tubes, and metal plates for multiple purposes in one machine

Strong power and efficient cutting

Gantry gear rack servo dual drive structure

Upgrade its cutting performance and stability once again

Enjoy high precision, quality, and stability to the fullest

Bringing an extraordinary cutting experience