production in one step!

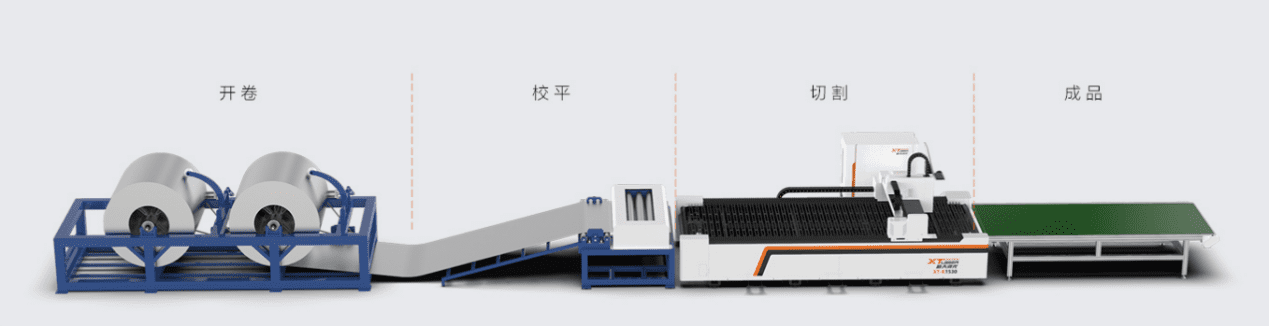

Automatic leveling and uncoiling

Accurate and intelligent feeding

Continuous and precise cutting

XT coil laser cutting machine

Building a smart production line

Building Hard Core Competitiveness

One machine can achieve multiple functions in one step

The gradual popularization of coil laser cutting machines has brought quality improvement to various industries and has become an important assistance for enterprises to start automated production. As a device with high cutting accuracy and production efficiency, the XT coil laser cutting machine has achieved an integrated automatic production line of uncoiling, leveling, feeding, cutting, and cutting during the production process, ensuring both surface quality and cutting speed, as well as improving the processing efficiency of laser cutting.

Four times the benefit of double roll feeding

Optimizing the processing method for double roll continuous operation

Breaking through conventional load-bearing limits

The weight of a single roll can reach seven tons

Multiplying work efficiency

Full automatic assembly line batch processing

Upgrading from single cutting to integrated processing production line

Capable of uncoiling, leveling, and cutting bare coil materials

One go, save labor

Production of surplus materials to maximize material utilization

Strength Online Precision Cutting

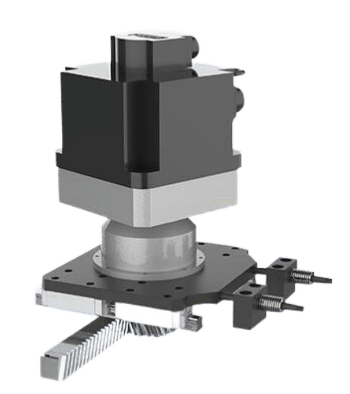

Equipped with ultra-high precision transmission structure

Transmission accuracy within ± 0.5mm

Linkage speed can reach 120m/min

Simultaneous cutting and feeding

Maintain higher accuracy

One machine can easily achieve automated production with multiple functions

24H continuous cutting

The laser cutting production line for coil materials can achieve continuous cutting without stopping for 24 hours, with uninterrupted cutting and feeding operation. Feeding, feeding, cutting, and unloading are carried out synchronously, with superior transmission system and precise cutting efficiency, significantly improving production and unloading, saving customers a lot of time.

More flexible production and processing

It can respond to changes in production requirements at any time. When the required parts change, the two-dimensional graphics can be modified through programming software to cut out the required parts, without the need for changes in equipment hardware structure. It has the flexibility to manufacture different products.

Intelligent production is more efficient

Adopting advanced layout software and control system, the product specifications and shapes can be quickly converted, and there is no need for manual operation from uncoiling to cutting. Intelligent transmission connection is used between leveling and cutting, with intelligent synchronization throughout the entire process. After cutting, synchronous feeding can be achieved, reducing the occurrence of excess waste, suitable for various batch product production.

More advantages, waiting for you to discover!

Breaking traditional processing methods

Integrating intelligent machinery with humans

XT coil laser cutting machine

No mold required for on-demand material extraction

Uncoiling, feeding, cutting, and cutting

Four major functions, one machine and dual functions

Creating more value for you