Nowadays, the application of steel structures creates strong “bones” for urban architecture. With the continuous breakthroughs and maturity of laser cutting technology, laser cutting equipment has become an important force in promoting the rapid development of China’s steel structure industry.

If you want to do good work, you must first sharpen your tools. In terms of cutting medium thick and high-strength steel plates, the XT Wanwa laser cutting machine has faster speed, better accuracy, and smoother cross-section. The large fiber laser cutting machine assists the steel structure industry and builds a modern new type of “toughness” city.

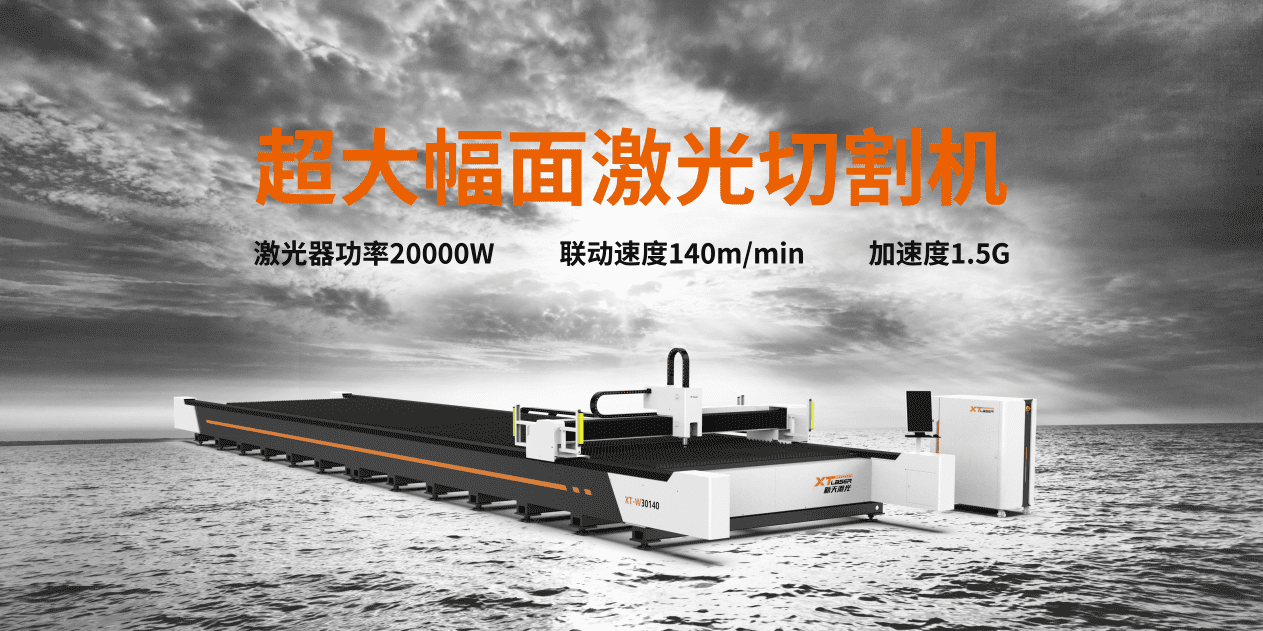

Recently, XT Laser delivered the 14m large format 20000W laser cutting machine as scheduled. As a benchmark enterprise in the steel structure field of Xi’an, CG Company is a comprehensive enterprise mainly engaged in steel Structural engineering and market processing, with extensive business, strong strength and rapid development momentum.

Large steel components have strict requirements for cutting equipment. Traditional equipment cutting involves multiple complex processes such as cutting, scribing, welding, and drilling, which are complex and time-consuming. After multiple inspections, the company believes that the XT laser cutting machine is excellent in terms of product quality and cutting efficiency, meeting the processing needs of our factory. The subsequent supporting “0 worry” service is even more reassuring, So I ultimately chose XT. The entry of the XT W3014 million watt laser cutting machine coincides with an urgent order. With its strong momentum and excellent performance, the daily processing volume in the workshop has rapidly increased, which has been unanimously recognized by the entire production team Mr. Shi praised this “new” friend in the workshop endlessly. This is not only CG company’s recognition of XT products, but also the trust of the market and many customers in the XT brand.

The Heritage and Genes of Made in China

Extra large format

Customized with extra large format

Cutting and forming of oversized steel plates in one go

Reduce cutting processes for more efficient cutting

Higher utilization rate of sheet metal, reducing production costs

High precision slag free

High precision bed

Achieve a positioning speed of 140m/min

High speed cutting without slag hanging

Easily handle customer cutting of various complex parts

High power laser

Excellent control system and real-time monitoring of cutting energy efficiency

High power laser head with higher motion rigidity

Assisting in significantly improving the cutting accuracy of steel structures

Achieve leapfrog improvement in production efficiency in customer workshops

Intelligent interconnection

Intelligent visual control system

Visually adjust laser power, gas type, and pressure

Platform real-time monitoring of device data

High opening digital intelligent cutting new mode

Submit answers with craftsmanship and quality

If excellent quality is the foundation for production and processing, then comprehensive and thoughtful service is the most powerful guarantee for safeguarding the operation of future machines. From the beginning, XT Service has been accompanying each other all the way, providing professional, thoughtful, and warm services to escort the entire journey.

Focusing on the process and process, strictly treating every detail, setting up a comprehensive inspection and evaluation system from multiple scientific dimensions such as product development, optical design, and physical performance, equipped with high-quality lasers, control systems, laser heads, and other core components. At the same time, conduct self inspection and self inspection before delivery, ensuring the quality of each piece of equipment through comprehensive and multiple measures. It is an honor for XT Laser to contribute to the construction of Xi’an, and it is its responsibility to add more impetus to the development of the steel industry.