Summary. Explore the history of 3D printing, from its 1980s inception to its rapid expansion today. Inventions by pioneers like Chuck Hull and Hideo Kodama have paved the way for various printer types and a future where 3D printing transforms industries worldwide.

For many, 3D printing is a relatively new concept that has only become more widely recognised and globally utilised in recent years. In actuality, 3D printing has been around since the 1980s and is quickly becoming one of the fastest growing industries. There are endless possibilities, from producing anything from toys to tools, houses to organs. Therefore, global industries are now realising the true potential of 3D printing.

In this post we’ll explore the history of 3D printing, who invented it and when. We’ll also take a look at where the industry is going in the years ahead.

Who invented 3D Printing?

It wasn’t until the early 1980’s that 3D printing truly began. However, the 1970s brought about an important time of theory surrounding the process. It was during this time that talks around the production of three-dimensional objects using additive layering began. This literally put the building blocks in place for the next decade.

Japanese Research

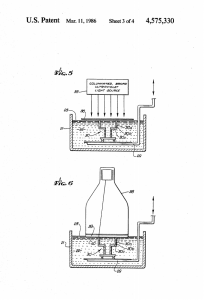

In 1981, Hideo Kodama of the Japanese Municipal Industrial Research Institute was awarded the first 3D printing patent. Kodama invented two additive methods to fabricate three-dimensional plastic models using photo hardening thermoset polymers. The UV exposure area would then be controlled by a mask pattern or a scanning fibre transmitter.

French Inventors

It would only take three years before a team of French inventors would file their patent on the stereolithography method: Alain Le Méhauté, Olivier de Witte, and Jean-Claude André. Similar to Kodama’s invention, this method would rely on UV light to successfully harden photopolymers. Unfortunately, the French General Electric Company decided to abandon the patent application. They cited a lack of business prospects at the time. To their detriment, stereolithography is still widely used in 3D printing today.

American Father Of 3D Printing

After that, it would the only take three weeks before an American would benefit from the French team’s lack of foresight. Chuck Hull went on to successfully file his patent for his very own stereolithography fabrication system. Hull is now widely seen as the ‘Father of 3D Printing’. He defined his process as a “system for generating three-dimensional objects by creating a cross-sectional pattern of the object to be formed”.

Who Was The Original 3D Print Inventor?

Many would argue that Kodama was the original inventor of this system. It would be years before Hull created his stereolithography machine and coined the term. However, Kodama’s contribution to the 3D Printing industry cannot be understated. He did make another extremely important and original contribution to what we now know as the history of 3D printing. Hull was the key developer of the STL file format which is the digital file that can be read by 3D printers. STL files are still a crucial and widely recognised element used today in 3D printing.

Without the development of the STL file format, the face of modern-day additive manufacturing would be very different. It is the vital combination of both hardware and software that has made it possible to design a 3D model on computers. In addition, have the ability to accurately reproduce it using a 3D printer.

Types of 3D Printers

Since its inception, 3D printing has quickly expanded over the years of history. Particularly during the 1990’s when a string of 3D Printing companies would emerge to push the tech forward. Each has significantly contributed to the development of the 3D printer. Creating many different models with their own unique capabilities.

There are a wide variety of 3D printers, each named based on the technology they use to function.

Related: Will 3D Printing Replace Manufacturing As We Know It?

Here we have listed the 9 main types of 3D printer below:

- Stereolithography (SLA) – This was the first 3D Printing method ever used and is still widely used today.

- Digital Light Processing (DLP) – Similar to Stereolithography, DLP works with photopolymers but uses digital micromirrors laid out on a semiconductor chip. The printing speed is much faster when compared to its counterparts. Additionally, is able to create much better resolution objects. It also uses less materials and therefore costs less.

- Fused Deposition Modelling (FDM) – This is one of the most popular technologies in use within 3D printing. It allows the user to print concept models and final products with engineering-grade thermoplastics.

- Electronic Beam Melting (EBM) – This method uses a power beam as its source but is much slower and more expensive to use.

- Laminated Object Manufacturing (LOM) – Although not as popular as other methods, LOM is one of the most cost effective and fastest printing option.

- Selective Laser Sintering (SLS) – SLS can use a wide variety of materials and is therefore popular for customising 3D objects.

- Selective Laser Melting (SLM )- This tech is widely used in aerospace manufacturing and for objects with complex geometries.

- Material Jetting (MJ) – Also referred to as wax casting, MJ is perfect for producing high resolution 3D objects.

- Binder Jetting (BJ) – You cannot print high res objects with this tech. However, BJ printing allows you to print objects in full colour by bonding layers together.

Related: Should I buy a 3D printer?

FAQ: The Evolution and Impact of 3D Printing

What is the history of 3D printing?

3D printing, though widely recognised today, actually began in the 1980s. The concept of additive manufacturing—building objects layer by layer—was theorized in the 1970s, laying the foundation for the technology we know today. The first 3D printing patent was awarded in 1981, and the technology has since rapidly evolved, transforming industries worldwide.

Who invented 3D printing?

While Hideo Kodama of Japan is credited with the first 3D printing patent in 1981, Chuck Hull, an American inventor, is often regarded as the “Father of 3D Printing.” Hull developed the stereolithography fabrication system in 1984, which remains a foundational technology in 3D printing today.

What are STL files and why are they important?

STL files, developed by Chuck Hull, are crucial in 3D printing as they provide the digital format that 3D printers read to create physical objects. Without STL files, the seamless translation of computer-generated designs to 3D printed models would not be possible, making them a cornerstone of modern additive manufacturing.

What types of 3D printers are available today?

3D printing technology has expanded significantly since its inception, with various types of printers designed for specific applications. These include:

- Stereolithography (SLA): The first 3D printing method, still widely used today.

- Fused Deposition Modelling (FDM): Popular for creating concept models and final products with engineering-grade thermoplastics.

- Selective Laser Sintering (SLS): Favored for customising 3D objects using various materials.

- Selective Laser Melting (SLM): Often used in aerospace for complex geometries.

Why is 3D printing considered transformative?

3D printing is revolutionising industries by enabling rapid prototyping, reducing costs, and minimising material waste. Its applications range from manufacturing tools and consumer products to creating medical implants and even entire buildings. The ability to produce complex, custom parts quickly and affordably makes it a game-changing technology for many sectors.

What is the future of 3D printing?

The future of 3D printing looks promising, with expectations that it will become a standard tool in homes, schools, and businesses. As technology advances, the cost of 3D printers is decreasing while their quality improves. This trend suggests that 3D printing will continue to integrate into everyday life, transforming how products are designed, manufactured, and consumed.

How can 3D printing benefit my business?

3D printing offers numerous benefits, including faster production times, reduced costs, and the ability to create complex, customized parts. For businesses, this means improved efficiency and innovation in product development, making it easier to stay competitive in a rapidly evolving market.

The Future of 3D Printing

In recent years, 3D printers have become increasingly accessible with the price dropping and the quality constantly improving. What we can take from the last ten years alone as well as the entire history of 3D printing is that it won’t be stopping anytime soon. The technology will continue to advance at a rapid rate. It is predicted by many that soon every home, school and business will have a 3D printer as an integral part of their day to day life.

The reduction in time, cost and materials that 3D printing provides suggests that the commercial and industrial world won’t take long to integrate this tech into their manufacturing processes. The ability to create fast, sustainable and affordable tooling alone is more than enough of an incentive to persuade global companies to capitalise on this innovative resource.

As with any new tech, there is skill required to understand how best to use it. Training is needed even to use CAD software to even generate the correct files that will run in a 3D printer. But when we look back at the history of technology, even with tech such as computers we can see that it doesn’t take much time for society to embrace the new and quickly adapt.

If you found this blog useful, why not take a look at a previous one: Are 3D Printed Parts Strong?