Tailored for mass rapid cutting of metal pipes

Equipped with intelligent control system

Can be paired with automation modules, labor-saving and easy to operate

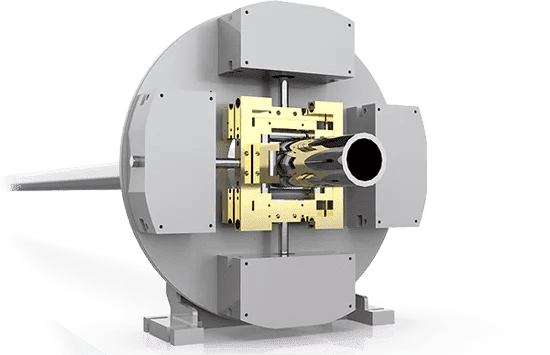

Precision pneumatic self centering chuck, automatic pipe clamping

Suitable for circular tubes, square tubes, rectangular tubes, etc

One machine with multiple functions, with a strong core

Invest in lower costs to achieve higher returns

Boosting production capacity, accuracy, and economic benefits

Efficient and precise cutting of “intelligence” is unstoppable

Maximum speed of processing tube length laser power chuck Maximum acceleration positioning accuracy of chuck

6.5M/9.2M 1000W-3000W 120r/min 1.2G ± 0.03mm

Double pneumatic chucks are upgraded with “intelligence”

Intelligent pneumatic clamping for greater clamping force

Heavy pipes are not loose or slippery

Automatic centering without scratching the workpiece

Adapt to different shapes of pipes for more stable feeding and increase production capacity

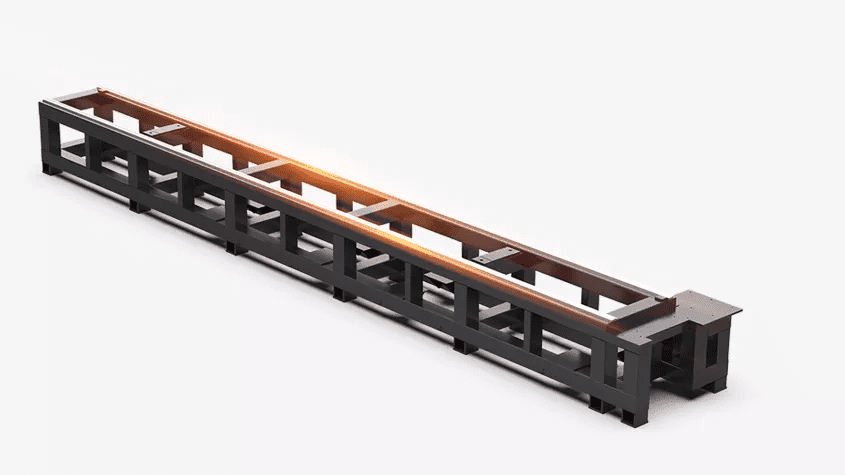

Stable bed with precise cutting

Heavy square tube welded bed

Made of thick steel plate welded for higher stability

High temperature annealing treatment, less heat absorption, preventing deformation

Provide strong support for precise processing of ultra-heavy pipes

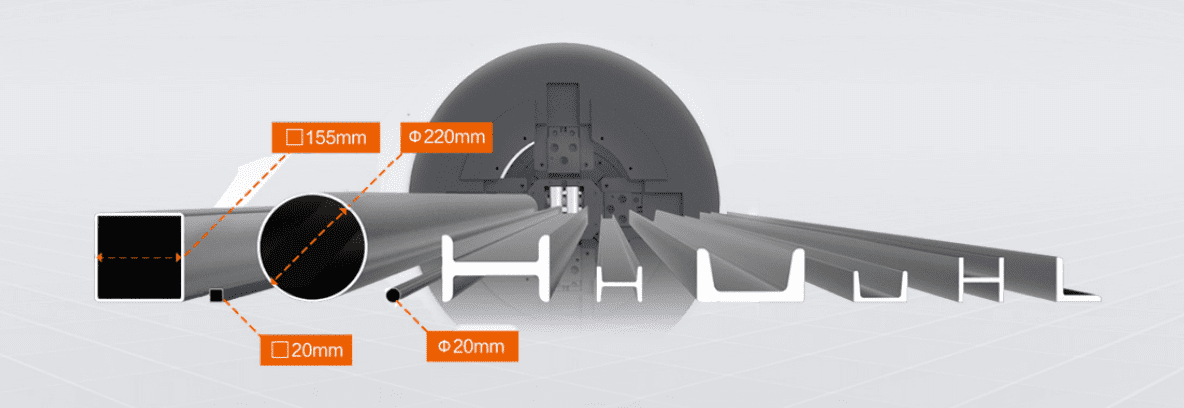

Breakthrough in pipe diameter with surging performance

Not only can traditional pipes such as circles be cut

Square and rectangular pipes, channel steel, angle steel H-shaped steel and other profiles

Specially shaped pipes, such as triangles and concave shapes, can also be easily cut

Solve the processing difficulties of various pipe materials with ease

Easy loading, safe and convenient

Can be equipped with automation devices to reduce labor intensity

More considerate human-machine interconnection, safe and efficient material rack with a load capacity of 3t

Batch processing without pressure, anti scratch design for workpieces

Effectively saving labor costs

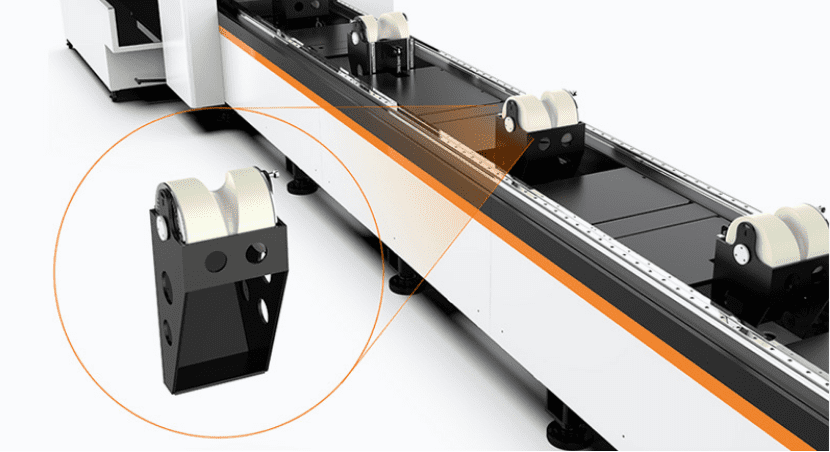

Automatic support installation is flexible and efficient

Adopting intelligent tube support design

Realize auxiliary loading and material support

Can solve the deformation problem during long pipe cutting process

Convenient adjustment and improved efficiency

Intelligent manufacturing upgrade is clear at a glance

Built in rich processing parameter library

Simple interface and efficient operation

Can be automatically called and modified according to the type of pipe, without the need for complex settings

Exclusive intelligent butler with a better understanding of pipe cutting

Crafted with precision, quality, and dedication

Equipped with laser radiation safety doors in the cutting area

Ensuring the safety of operators

Equipped with a receiving box for easy and timely cleaning

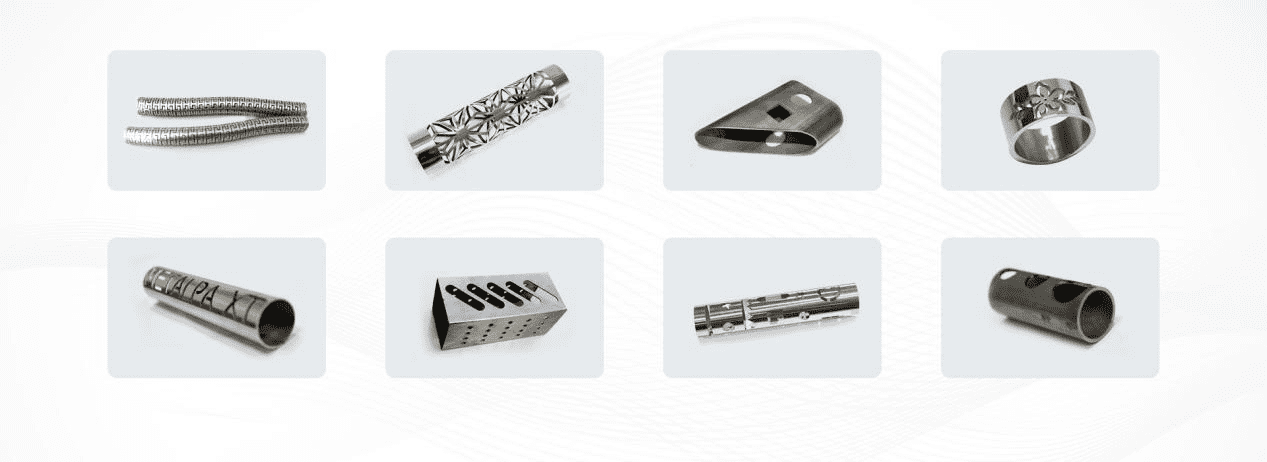

Process and sample display

Laser rapid cutting of various metal pipes

High precision, full-time cutting, digital intelligent control

Strong performance, more than just one side

Specially designed for high-speed cutting of large-sized pipes/profiles

In various fields such as rice processing, automobile manufacturing, mechanical equipment, etc

Becoming a “must-have model” for high-end metal pipe processing

XT Laser T Series Pipe Laser Cutting Machine

Leading the way with a hard core, the choice of wisdom!