Choosing the Right Process

Material and Design Factors

When you pick between laser marking and laser engraving, you must think about your material and design. Different materials react in their own way to each process. Metals like stainless steel or titanium can use both methods. But you might need a fiber laser for deep marks that last. Plastics often work better with CO2 lasers. These lasers can mark the surface without hurting it.

You also need to decide how strong you want your mark.Laser engraving makes marks that stay even if they get scratched, heated, or cleaned with chemicals. This is important for things like airplane or medical parts. These marks must not fade. Laser marking is good for designs on the surface that need to be exact. It is faster and does not harm soft materials. If you want special marks or tiny details, laser marking is a good pick.

Other things to think about are:

- How much heat the material can take and how it absorbs the laser

- If the surface is shiny or has a coating

- Rules for your industry about tracking and how long marks must last

Practical Selection Guide

You can use a simple chart to help you choose the right process. Look at this table:

| Criteria | Laser Marking | Laser Engraving |

| Material Compatibility | Metals, plastics, ceramics, glass | Metals, wood, acrylic, plastics, stone |

| Durability | Good, but may wear with heavy use | Excellent, withstands harsh conditions |

| Speed | Fast, good for high-volume jobs | Slower, best for deep, lasting marks |

| Precision | High, great for small codes and logos | High, adds depth and texture |

| Cost | Lower operating costs | Higher due to slower speed |

| Best Use | Traceability, electronics, fine detail | Industrial labels, signage, gifts |

Tip: Pick laser marking if you want fast, detailed, and cheap marks. Choose laser engraving for deep, tough marks or when you want to make products special for a long time. Laser engraving is great if you want to add names or designs that will not go away.

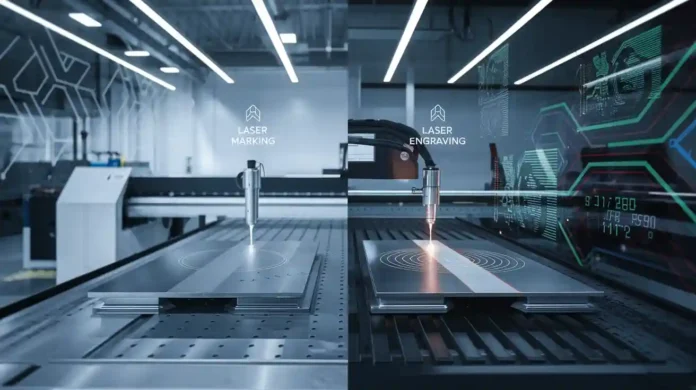

Laser marking changes only the top of the surface. It helps you quickly see and read marks. Laser engraving cuts into the material to make deep marks that last a long time.

- Laser engraving is strong and very exact for hard jobs.

- Laser marking is best when you need fast and easy tracking in busy factories.

| Step | Key Question | Recommendation |

| 1 | What is your material? | Use the right laser for it |

| 2 | What mark do you need? | Pick deep or surface marks |

| 3 | What is your durability need? | Choose for lasting or looks |

Think about what your product needs and what is popular in your industry before you pick.