Here’s where it makes a serious impact:

Printed Circuit Boards (PCBs)

PCBs are the beating heart of every electronic device — and keeping track of them is critical.

With UV laser marking, you can engrave serial numbers, batch codes, and assembly data directly onto the board without damaging the circuits.

This means faster assembly tracking, easier troubleshooting, and airtight quality control — all while keeping your production line humming.

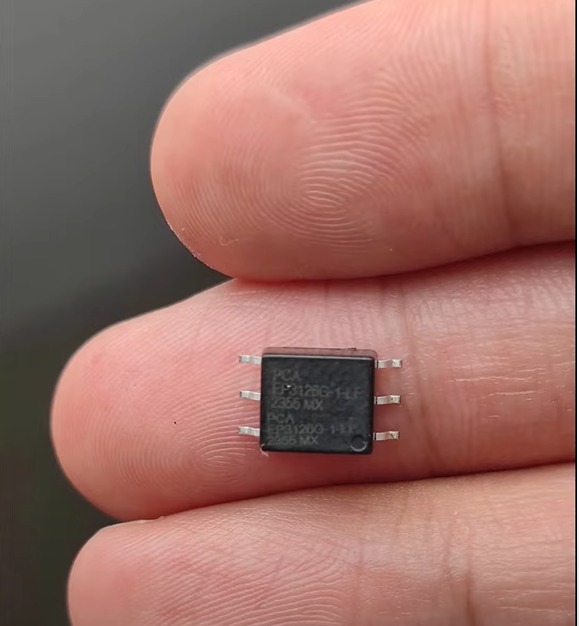

Semiconductors and Microchips

These tiny but mighty parts are super sensitive, and even a little heat can destroy them.

That’s why UV lasers are the go-to: they mark with minimal thermal impact, leaving clear, precise IDs that help with lot tracking, warranty management, and authenticity verification — all without compromising the chip’s performance.

Connectors and Cables

Ever tried to trace a mystery cable in a tangled mess?

Laser-marked connectors and cables solve that headache.

By engraving permanent codes or identifiers directly onto the surface, you make maintenance, repairs, and replacements so much faster and more reliable — especially when cables are hidden inside tight systems or industrial equipment.

Consumer Electronics Components

Phones, laptops, smart gadgets — they’re everywhere, and so are counterfeits.

UV laser marking doesn’t just help with production control; it also builds brand protection.

Permanent, high-contrast logos, serial numbers, and anti-counterfeiting marks make it easier to trace legitimate products and shut down knockoffs before they reach your customers.