How to Etch Metals

The process will vary depending on the type of metal and your preferred etching method. However, the general process is as follows.

Choose Your Material

Of course, the first step to etching metals is choosing your desired material. Some common materials to work with are copper, brass, steel, aluminum, etc. Steel can also be etched, only it involves a more rigorous etching process.

Prepare the Metal Surface

Before you start etching, ensure the metal surface is free from dust, oil, stain, dirt, etc. This step is essential to the etching process, as dirt, stain, and oil can impede the subsequent film or screen-printing ink from adhering firmly to the metal surface.

In addition, you should degrease the surface depending on the degree of oil contamination. This can be done by washing the metal surface with soap and water and wiping it with a degreaser. You could as well electro-degrease to ensure complete degreasing. Ensure the surface is completely dry before etching.

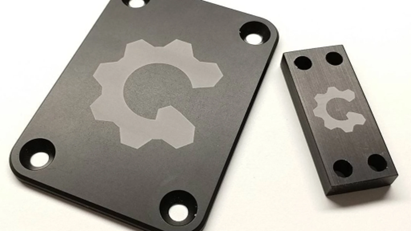

Create Your Design.

If you use the laser etching method, design your pattern and design using computer software. There is also the option of manually drawing your design on tracing paper or directly on the material.

Apply the Resist Material

The resist is a material that protects the metal surface from being etched. Carefully cut out the resist’s size to match the size of your metal, then paste the resist directly on the metal surface, ensuring any air bubble is completely removed.

Some materials that can be used as resist are tape and sharpie.

Etch the Metal

Next up is etching your material. This step varies with the type of etching you are using. However, generally, after firmly sticking the resist to the surface of the metal, carefully submerge the metal in a plastic container containing your etching solution.

How long the metal will stay in the etching solution will depend on the strength and type of the solution. It is advised that you follow the instruction on the manufacturer’s label. Once the desired depth is attained, remove the metal from the solution.

If you use the laser method, you have to prepare the material and place it in the machine.

Remove the Resist Material.

After removing the metal from the solution, rinse thoroughly with water and gently remove the resist with a tool. You must be careful with the step to prevent scratching the metal surface.

Clean the Metal Surface.

Clean the metal surface thoroughly to remove any debris from the resist. Preferably, use a scrubbing pad or abrasive cloth. While etching, ensure it’s in a well-ventilated environment, and you are well-covered.