XT laser-fiber laser cutting machine

There are thousands of domestic manufacturers of optical fiber laser cutting machines, and even more. So many laser cutting machine manufacturers have brands. How to choose laser metal cutting machine?What should we pay attention to when purchasing optical fiber laser cutting machines? The selection of laser cutting machine, especially the fiber laser cutting machine, you must have a look at its software system, as well as its hardware facilities. The general hardware facilities include its fiber laser and cutting head. In addition to collecting information about the enterprise’s brand strength and reputation on the Internet, people outside the industry also need to have a deep understanding of various parts and processing application knowledge of a fiber laser cutting machine. Fiber laser cutting machines are expensive, often hundreds of thousands of millions. There are many elements that need to be understood during the purchase of laser cutting machines. The following summarizes some selection techniques and methods for your reference only.

1、 Parts to pay attention to when purchasing optical fiber laser cutting machine

A. Control software

The control software, also known as the numerical control system, will also affect the cutting accuracy of the optical fiber laser cutting machine. Generally, the optical fiber laser cutting machine produced by manufacturers adopts the imported numerical control system, but some manufacturers are developing CUT software themselves, but it is relatively rare.

B. Fiber laser

The fiber laser is the core component of the fiber laser cutting machine, and also the “power source” of its cutting operation. The length of service life, cutting speed and cutting quality of a device depend largely on the fiber laser. Frankly speaking, the performance of foreign fiber lasers is not one or two grades better than that of domestic fiber lasers, especially the high-power fiber lasers above 700W. The reason why some manufacturers of fiber laser cutting machines with the same power are expensive is that they use internationally well-known fiber laser brands such as SPI, IPG, rofin, etc. Many manufacturers claim to use imported fiber lasers, but in fact, domestic lasers are used to replace the imported fiber lasers. How to distinguish? In fact, it is very simple. Select materials of the same thickness and go to two different manufacturers for proofing, one of which must be a large manufacturer and an old brand. Then select the same power machine and compare the cutting speed and cutting quality.

C. Cutting head

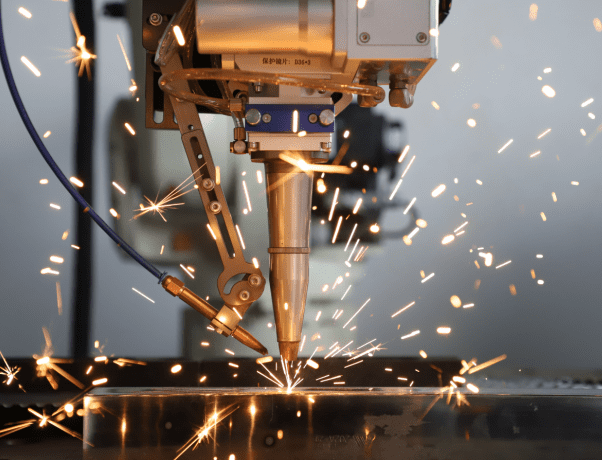

The cutting head of laser cutting machine is a laser output device, which is composed of nozzle, focusing lens and focusing tracking system. The cutting head of the laser cutting machine will walk according to the set cutting path, but the height of the laser cutting head needs to be adjusted and controlled under different materials, different thicknesses and different cutting methods. The high-power optical fiber cutting machine produced by Guangzhou Aoling Intelligent adopts a cutting head with leapfrog function, which can adjust its height dynamically, which is very convenient.

D. Servo motor

Servo motor refers to the engine that controls the operation of mechanical components in the servo system. It is a kind of auxiliary motor indirect speed change device. It provides the power for the operation of the fiber laser cutting machine, and also affects the cutting accuracy. In the servo system, the engine that controls the mechanical operation is a kind of auxiliary motor indirect transmission device. The gantry rack servo drive structure, coupled with high-quality servo motor, can effectively ensure the cutting accuracy, positioning speed and repeated positioning accuracy of the laser cutting machine. The servo motor of high-power optical fiber laser cutting machine generally adopts the well-known Japanese motor brand “Yaskawa Motor”. I believe that many friends in the machinery manufacturing industry are familiar with the 100-year-old Yaskawa Motor. Therefore, the motor is also a very important component, and you must pay attention to it when purchasing.

E. Cooling device

The power of the fiber laser machine is large, and the heat of the fiber laser is large when it works. In order to ensure the service life, it is necessary to select a professional matching cooling device. The water cooler is the cooling device of the laser cutting machine, which can quickly and efficiently cool the laser, spindle and other devices. The current water chillers contain the advanced functions of input and output control equipment switch, cooling water flow, high and low temperature alarm, and the performance is more stable, so as to ensure that the fiber laser cutting machine works under constant temperature and prolong the life of the fiber laser.

F. Machine tool structure

Machine tool structure is an important factor affecting the cutting accuracy, stability and durability of the fiber laser cutting machine. The cutting accuracy of the fiber laser cutting machine will decline with the increase of the service time of the machine tool. Machine wear and aging of transmission structure components are all the reasons for the decline in accuracy.

2、 Performance knowledge to pay attention to when purchasing optical fiber laser cutting machine

To sum up, the performance of fiber laser cutting is nothing more than three points: how thick can be cut, how many blocks can be cut, and how good can be cut?

Some manufacturers claim that 2000W can cut 12mm or more thick carbon steel, which can be cut and moved during actual cutting, and the cutting effect seems to be barely acceptable. But here we should pay attention to the problem that the machine has excessive performance and performance overdraft. Like an immature child, if he is allowed to do some physical work for a long time, it will cause great damage to his body.

These are the problems that should be paid attention to when selecting a laser cutting machine. To ensure the best performance of a high-quality laser cutting machine, you must check its hardware and software facilities. Only when the software and hardware facilities are good can you choose a good laser cutting machine!