In the world of additive manufacturing, 3D printers have become indispensable tools for additive manufacture. But what if you could enhance the capabilities of your 3D printer even further? Enter the 3D scanner, the device that captures your physical objects in immense detail and converts them into digital 3D models. When combined with a 3D printer, a scanner opens up endless possibilities for reverse engineering, rapid prototyping, and precision manufacturing.

In this blog, we’ll explore how the scanners we offer at Central Scanning can elevate your reverse engineering operation. From improving design accuracy to enabling the rapid creation of custom parts, we’ll break down how these two technologies work hand in hand to transform the way you create, modify, and produce objects. Whether you’re a hobbyist or a professional, understanding the symbiotic relationship between 3D scanning and printing is key to unlocking the full potential of your workflow. Let’s dive into how this powerful duo can revolutionise your 3D printing experience.

What is a 3D scanner

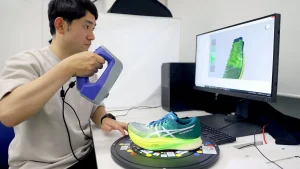

3D scanning is the process of capturing the physical dimensions, shape, and appearance of an object or environment to create a digital 3D model. This is done using a 3D scanner, which employs various technologies like lasers, structured light, or cameras to scan the object’s surface and collect data. The scanner records thousands of data points that represent the object’s geometry. The resulting data can then be used for a variety of purposes, including 3D printing, virtual simulations, reverse engineering, quality control, and more.

How a 3D Scanner enhances the 3D printing process

A 3D scanner enhances the 3D printing process by creating an accurate digital replica of a physical object, enabling reverse engineering, customization, and precise reproduction. It captures intricate details and geometries, ensuring high accuracy for better print quality and reducing waste. The scanner also speeds up the process by quickly providing digital models, allowing for faster prototyping and design adjustments. Additionally, it aids in quality control by comparing printed objects to their original design, ensuring the final product meets specifications. Overall, 3D scanning streamlines workflows and enhances the capabilities of 3D printing.

Benefits of combining a 3D scanner and 3d printer

Combining a 3D scanner and a 3D printer offers several key benefits. First, it enables reverse engineering, allowing you to easily recreate or modify existing objects without needing original design files. It also facilitates customization by capturing real-world objects, making it possible to tweak designs for unique, tailored results before printing. This combination ensures high precision and accuracy in the final printed object, as the 3D scanner captures every detail of the original object, reducing errors and material waste. Additionally, it speeds up the prototyping process, enabling rapid iterations and quicker adjustments. Overall, using both technologies together enhances workflow efficiency, improves design flexibility, and allows for seamless integration of real-world objects into digital fabrication.

When 3D scanning parts to print, the Markforged printers are much smaller desktop printers which have Onyx material (carbon fibre nylon composite), at Central Scanning we mostly recommend Mark 1 and Mark 2. The material has great functional properties so the parts can be printed as is with good strength and good wall finish, which are great for making fixtures.

Stratasys Fotus 450mc is great for its higher end material, typically we print ULTEM at Central Scanning and this printer has a much bigger print volume for larger parts. We offer 3D scanning and 3D printing services tailored to your businesses needs, you can find out more by contacting us and discussing with one of our experts.

Real-World Applications of 3D Scanning in 3D Printing (case study examples for different industries)

When used together, 3D scanning and 3D printing create powerful solutions across a variety of industries. In manufacturing, they enable the rapid reverse engineering of broken or obsolete parts by scanning existing components and printing exact replicas or improved versions. In healthcare, 3D scanning can capture a patient’s unique anatomy, allowing for the creation of custom prosthetics, implants, or even dental models that are then printed to fit the individual perfectly.

The automotive industry uses this combination for prototyping and customizing parts, improving design iterations and reducing lead times. In architecture, 3D scanning captures the details of existing structures for renovation or digital modelling, while 3D printing creates precise scale models or elements needed for construction. Art and historical preservation benefit as well, where 3D scanning allows for the digital preservation of artifacts, which can then be 3D printed for restoration or for creating replicas for display. Overall, using 3D scanning and 3D printing together enhances accuracy, customization, and efficiency across numerous fields.

We helped Cerebra Innovation Centre to create custom 3D-printed children’s helmets. Cerebra worked with Imogen, a keep horse rider with spastic diplegia, a form of cerebral palsy. Imogen struggled to find a horse-riding helmet that fit her head and protected her from the safety risks of horse riding. Central Scanning used the Artec Eva 3D scanner to scan Imogens head, then 3D printed the shell model captured by the scan with layers of fibreglass and Kevlar are laid up using epoxy resin to make an extremely strong outer shell.

Choosing the right 3D scanner for your 3D printer

Our team at Central Scanning can help you to understand which 3D scanner and 3D printer are most suited to your requirements. Choosing the right 3D scanner is the most important for achieving a high quality model to then 3D print. Scanner success depends on factors such as scan resolution, object size, scanning speed, ease of use, compatibility, and budget.

The Artec Micro II is great for small parts and good price (something the size of an apple or smaller) and the Artec Spider II can be a great option if you need small to medium parts with handheld flexibility (high resolution and good accuracy). If you require high detail for complex objects, high resolution and accuracy are going to be the deciding factors. The GOM SCAN 1 delivers very high accuracy as well as resolution and is very flexible in parts size. For larger items, industrial or desktop scanners may be the best option, while handheld scanners offer flexibility for smaller objects. By evaluating these elements, you can select a 3D scanner that best complements your 3D printing needs.