[ad_1]

Exquisite craftsmanship and uniqueness

One click switching according to the “type” desired

One machine is done, one step to victory!

Breaking convention and changing traditional manufacturing with technology

Glass, due to its hard and brittle properties, poses great difficulties in processing, especially in the cutting and processing of ultra-thick glass, which has always been a technical challenge.

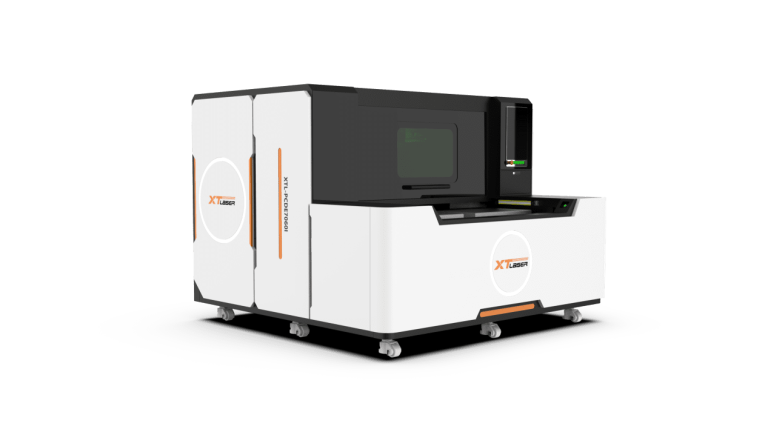

The XT Laser Infrared Picosecond Glass Cutting Machine adopts an imported servo driven linear motor, which effectively ensures the processing speed and accuracy of the equipment; Integrated structural design, easy to integrate; The mechanical and electrical structure is more exquisite, with a beautiful appearance, which can achieve complex pattern cutting with small edge breakage and high yield, helping enterprises reduce costs and improve processing efficiency.

High speed precision cutting with professional quality

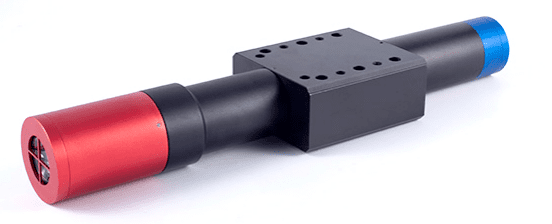

Bessel laser cutting

Excellent laser filament forming technology

Processing efficiency several times higher than CNC

Cutting speed can reach up to 1200mm/s

Working wavelength up to 1064nm

19mm thick glass directly cut through

Fully automatic loading and unloading processing with ease

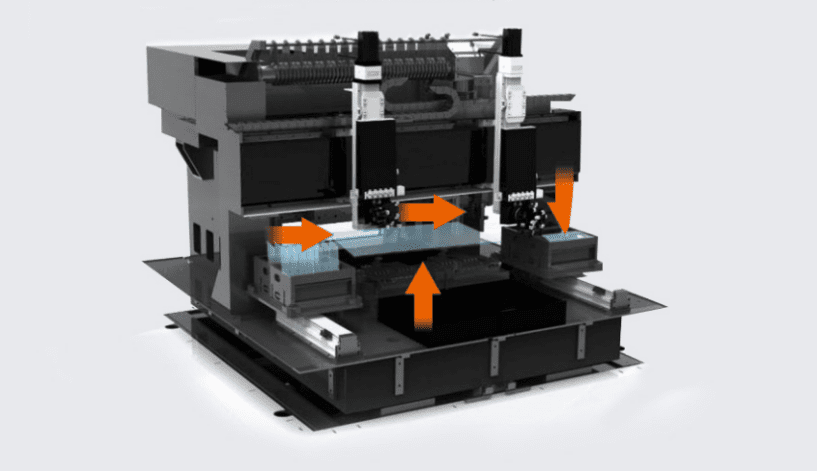

Automatic switching of dual Y interaction platform

Asynchronous loading and unloading structure precise connection

Dual platform efficient processing

Save loading and unloading time

Multiplying processing capacity

The surging performance unleashes its edge

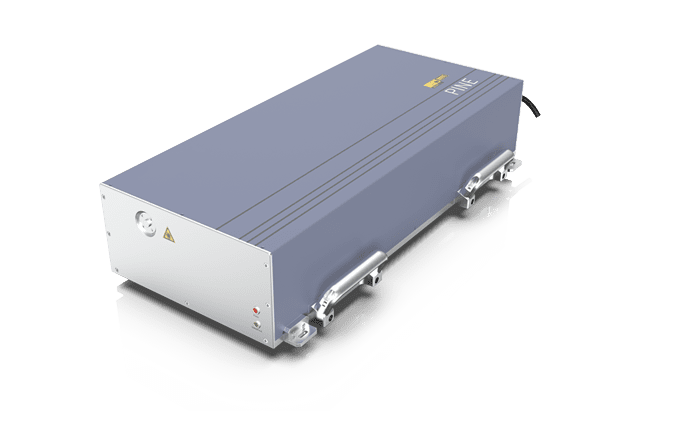

Laser adopts independent research and development to manufacture core seed sources

Picosecond laser beam emitted at a speed of<10 ps

Processing of any graphic size without pressure

Excellent beam quality

Neat cutting edges with good verticality

Continuous innovation only creates greater value for customers

New Process Technology of Infrared Picosecond

Breakthrough in achieving one size fits all for 19mm thick glass

Full page cutting of 3C industry new materials such as mobile phone camera protection film

Replacing traditional CNC machining mode

Picosecond laser wire cutting process

Adopting the third-generation picosecond laser processing technology, cutting through with one go

Linear motor PSO control

Micron level accuracy, synchronized path control implementation, and irregular cutting

Customized automated loading and unloading system

Automated configuration, less loading and unloading time, time-saving and labor-saving

Mechanical vision compensation

Alignment CCD and telecentric vision lens, automatic recognition, offset correction compensation

Splitting of high-power CO2 laser

Perfect separation of cutting trajectory lines, smooth product edges, small edge breakage, and excellent processing quality

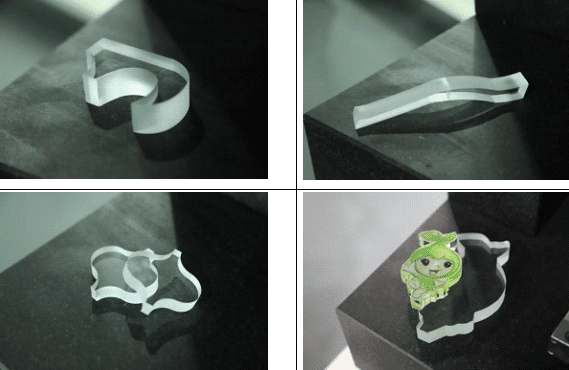

Cutting sample display

The XT Laser Infrared Picosecond Dual Platform Laser Glass Cutting Machine can be applied to the rapid cutting of various brittle materials such as glass and sapphire, as well as its supporting crack processing process, achieving complex pattern cutting with high precision and excellent quality of finished products. It not only helps enterprises reduce costs, but also greatly improves workpiece yield and processing efficiency.

Breaking through conventions and constraints

XT Laser Infrared Picosecond Dual Platform Glass Cutting Machine

Setting off another wave of “speed of light”

Intelligent control and fearless cutting of alien shapes at will

Laser kinetic energy one click excitation

Entering the “Light” Era of Glass Cutting

[ad_2]

Source link