Diverse Marking Techniques for Traceability and Identification

Marking machines employ a range of technologies to generate unique, durable imprints on products. The three most prevalent are laser marking, dot peen marking, and inkjet marking. Each boasts its own merits and is ideally suited to distinct types of materials and use cases:

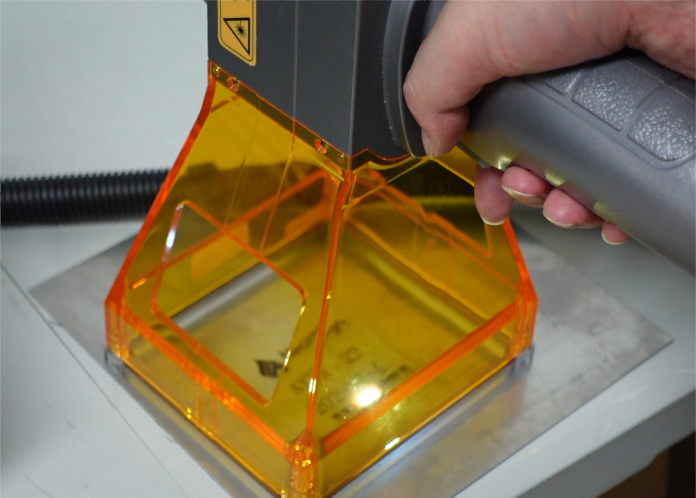

Laser Marking

This technique deploys lasers to etch information onto a surface. It’s accurate, offering high-resolution marking, and excels in marking diverse materials, including but not confined to metals, ceramics, and plastics. Laser marking is perfect for applications demanding small, highly-detailed imprints, such as QR codes or intricate logos. However, these machines can be pricier and require trained operators for safe handling.

Dot Peen Marking

Alternatively known as pin marking, this method utilizes a pin to indent the surface with a series of dots to shape characters or designs. It’s extremely durable and well-suited for metals and tougher materials. Dot peen marking is often used in industries where products are exposed to harsh conditions and necessitate marks that can withstand wear and tear.

Inkjet Marking

Inkjet markers employ ink to print information on a surface. These are versatile machines that can work with a variety of materials. They are exceptional for high-speed applications as they can print swiftly without contacting the product surface. However, the marks made by inkjet machines may not be as enduring as those made by laser or dot peen marking.

When selecting a marking technology, it’s crucial to ponder over the nature of your products, the environment they will be utilized in, and the longevity required of the mark. Each technology possesses its unique strengths, and the most suitable one will hinge on your specific needs and circumstances.