Are you in the market for a laser engraving marking machine, but feeling overwhelmed by the options available? Look no further! This comprehensive guide will walk you through everything you need to know to choose the perfect machine for your business needs.

Laser marking and engraving machines have become increasingly popular in a wide range of industries, from manufacturing to jewelry making. With their ability to create precise and permanent marks on various materials, these machines offer incredible versatility and efficiency.

In this guide, we will cover the different types of laser marking and engraving machines, their features, and the factors you should consider when making a decision. Whether you need a machine for marking serial numbers on parts or engraving intricate designs on custom products, we’ve got you covered.

Not only will we help you understand key technical specifications and functionalities, but we will also provide practical tips and considerations to ensure that you make an informed choice. So, let’s embark on this journey together and find the perfect laser marking or engraving machine for your business.

Different types of Laser Engraving Marking Machines

When it comes to laser marking and engraving machines, there are several different types to choose from. Each type has its own unique features and capabilities, making it important to understand the differences before making a decision.

1. Fiber Laser Marking Machines: Fiber laser marking machines use a fiber laser source to generate a high-intensity laser beam. These machines are known for their high-speed marking capabilities and are often used for marking metal materials such as stainless steel and aluminum. Fiber laser marking machines are also highly reliable and require minimal maintenance.

2. CO2 Laser Engraving Machines: CO2 laser engraving machines utilize a carbon dioxide laser to engrave or cut materials. These machines are commonly used for engraving wood, acrylic, leather, and other non-metal materials. CO2 laser engraving machines are known for their versatility and precision, making them ideal for applications that require intricate designs or fine details.

3. UV Laser Marking Machines: UV laser marking machines use a UV laser source to create marks on a wide range of materials, including plastics, glass, and ceramics. These machines are highly efficient and offer excellent marking quality, making them popular in industries such as electronics, medical devices, and cosmetics. UV laser marking machines are also known for their ability to mark transparent materials without causing damage.

Factors to consider when choosing a Laser Engraving Marking Machine

Choosing the right laser marking and engraving machine for your business requires careful consideration of several factors. By understanding these factors and how they relate to your specific needs, you can make an informed decision that will benefit your business in the long run.

1. Material Compatibility: One of the most important factors to consider is the compatibility of the machine with the materials you plan to mark or engrave. Different machines are designed to work with specific materials, so it’s crucial to choose a machine that can handle the materials you work with regularly. Consider the thickness, hardness, and composition of the materials to ensure compatibility.

2. Marking or Engraving Depth: Depending on your requirements, you may need a machine that can create shallow marks or deep engravings. Some machines offer adjustable settings, allowing you to achieve different depths depending on the application. Make sure to evaluate the marking or engraving depth capabilities of each machine you consider.

3. Speed and Productivity: The speed at which a machine can mark or engrave materials is an important consideration, especially for businesses with high production volumes. Look for machines that offer fast marking speeds without compromising on precision and quality. Additionally, consider the machine’s productivity features, such as automated loading and unloading systems, to maximize efficiency.

Popular applications of laser marking and engraving machines

Laser marking and engraving machines are used in a wide range of industries and applications. Here are some of the most popular applications:

1. Product Identification and Traceability: Laser marking machines are commonly used for product identification and traceability purposes. Whether it’s marking serial numbers, barcodes, or QR codes on manufactured parts, laser marking provides a permanent and tamper-proof solution. This is particularly important in industries such as automotive, aerospace, and electronics.

2. Personalization and Customization: Engraving machines are often used for personalization and customization purposes. From engraving names and messages on jewelry pieces to creating unique designs on promotional items, laser engraving offers endless possibilities. This makes engraving machines popular in the jewelry, giftware, and promotional product industries.

3. Art and Design: Laser marking and engraving machines are also widely used in the art and design world. Artists and designers use these machines to create intricate patterns, textures, and designs on various materials. Laser technology allows for precise and detailed engraving, making it a preferred choice for artists working with wood, acrylic, and other materials.

Important features to look for in a Laser Engraving Marking Machine

When evaluating laser marking and engraving machines, there are several key features to consider. These features can greatly impact the machine’s performance, ease of use, and overall suitability for your business needs.

1. Laser Source and Power: The type and power of the laser source are crucial factors that determine the machine’s capabilities. Consider the type of laser source (fiber, CO2, UV) that best suits your application. Additionally, evaluate the power output of the laser source, as higher power can result in faster marking or engraving speeds.

2. Software and Control System: The software and control system of a laser marking or engraving machine play a significant role in its usability and functionality. Look for machines that offer user-friendly software with advanced features such as vector graphics support, variable data printing, and image processing capabilities. A well-designed control system can also enhance the overall user experience.

3. Work Area Size: The size of the machine’s work area determines the maximum dimensions of the materials you can process. Consider the sizes of the items you plan to mark or engrave and choose a machine with a work area that can accommodate them comfortably. It’s also worth considering whether the machine offers adjustable or expandable work areas to accommodate future needs.

Steps to take before purchasing a laser marking and engraving machine

Before making a final decision and purchasing a laser marking or engraving machine, there are several steps you should take to ensure a successful implementation:

1. Assess your Needs: Evaluate your business requirements and determine the specific applications for which you need a laser marking or engraving machine. Consider factors such as material compatibility, marking or engraving depth, and production volume to narrow down your options.

2. Research and Compare: Conduct thorough research on different machine models and brands. Read customer reviews, visit trade shows or exhibitions, and consult with industry experts to gather information and compare features, performance, and prices.

3. Request Samples and Demos: If possible, request samples or demonstrations from machine manufacturers or distributors. This will allow you to evaluate the quality of the marks or engravings, test the machine’s capabilities, and assess its ease of use.

4. Consider After-Sales Support: Look for manufacturers or distributors that offer reliable after-sales support, including technical assistance, training, and spare parts availability. A strong support system is crucial to ensure smooth operation and minimize downtime.

Top brands and manufacturers of laser marking and engraving machines

When it comes to laser marking and engraving machines, there are several top brands and manufacturers that consistently deliver high-quality products. Consider the following brands when researching and comparing machines:

1. Epilog Laser: Epilog Laser is a renowned manufacturer of CO2 and fiber laser engraving machines. Known for their reliability, precision, and user-friendly software, Epilog Laser machines are widely used in various industries.

2. Trotec Laser: Trotec Laser offers a wide range of laser marking and engraving machines, including CO2, fiber, and UV models. Trotec machines are known for their advanced features, high-speed performance, and excellent customer support.

3. Thinklaser: Of course we have to add ourselves to this list. Thinklaser specialises in laser engraving and marking machines for industrial applications. With a focus on durability, versatility, and efficiency, Thinklaser machines are trusted by businesses worldwide. For the more straightforward applications we have our desktop LightScribe Laser Engraving Marking Machine. For those specialist, niche applications where one size does not fit all, we have our LightWriter range of bespoke Laser Engraving Marking Machines.

Maintenance and care tips for Laser Engraving Marking Machines

Proper maintenance and care are essential to ensure the longevity and optimal performance of your laser marking or engraving machine. Here are some tips to keep in mind:

1. Regular Cleaning: Regularly clean the machine’s optics, lenses, and filters to remove dust and debris. Follow the manufacturer’s guidelines for cleaning solutions and procedures to avoid damaging sensitive components.

2. Calibration and Alignment: Periodically calibrate and align the machine to ensure accurate marking or engraving results. This may involve adjusting the laser beam alignment, focus, and power settings.

3. Checking and Replacing Consumables: Keep track of consumable parts such as laser tubes, lenses, and filters. Regularly check their condition and replace them as needed to maintain optimal performance.

4. Operating Environment: Ensure that the machine is placed in a clean and well-ventilated environment. Avoid exposing the machine to extreme temperatures or humidity, as this can affect performance and longevity.

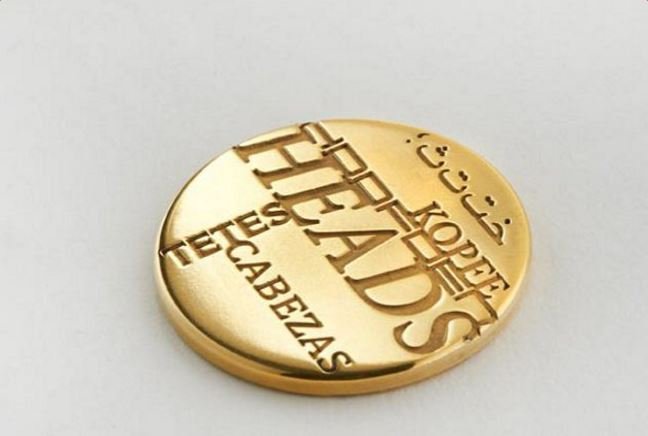

Processed parts from a Laser Engraving Marking Machine Gallery

Conclusion: Making the right choice for your business

Choosing the right laser marking or engraving machine is crucial for the success of your business. By considering factors such as material compatibility, marking or engraving depth, and machine features, you can make an informed decision that meets your specific needs.

Remember to thoroughly research and compare different machine models and brands, request samples or demonstrations, and consider after-sales support before making a final purchase. With proper maintenance and care, your laser marking or engraving machine will serve as a valuable asset for your business for years to come.

So, embark on this journey with confidence, and find the perfect laser marking or engraving machine to take your business to new heights.

FAQ’s

What is the difference between laser engraving machine and laser marking machine?

A laser marking machine will mark the surface of the material without removing any material.

A laser engraving machine removes or ablates the material leaving the underlying material bare.

It is possible for the same laser system to act as both a laser marking and engraving machine. E.g. A fibre laser can engrave metals, but mark plastics such as ABS.

How much does a laser marking machine cost?

Prices can vary dramatically between manufacturers, the type of laser source used and the power of the laser source and the application. Thinklasers desktop Lightscribe can cost between £8k and £18K, while our bespoke Lightwriter solutions can cost from £35k.

Is it worth buying a laser engraving machine?

There are a diverse number of applications for laser engraving machines. Finding a high value or high volume application or niche is certainly possible. It has been known for some companies to get a 1 job payback period on a laser machine purchase.