XT LASER picosecond glass cutting machine has mature technology and high quality, and can achieve high-precision and high-environmental cutting. It has entered the practical stage in the application of cutting touch display glass and mobile phone backplane glass. It should be put into the market to serve the majority of users. It realizes efficient and low-cost cutting of glass materials.

Let’s take everyone to deeply analyze this XT dual-platform picosecond glass cutting machine to see what is so good about it?

1. Exquisite workmanship and perfect effect

XT infrared picosecond dual-platform glass cutting machine adopts picosecond cutting technology to directly cut through the material, ultrashort pulse processing without heat conduction, suitable for high-speed cutting of glass materials; equipped with CCD visual scanning, automatic target positioning, offset correction compensation , “Unlimited deviation correction”, the maximum processing range is 750mm×550mm; supports a variety of visual positioning features, such as crosses, solid circles, hollow circles, L-shaped right-angled edges, image feature points, etc.; can customize automatic cleaning, visual inspection sorting, automation The loading and unloading system satisfies the ergonomic design and makes the processing “labor-saving and rest assured”; the research and development design of the laser micro-machining system, technology accumulation, stable performance, no consumables, um-level precision, synchronization of path and control, and realization of “special-shaped cutting”.

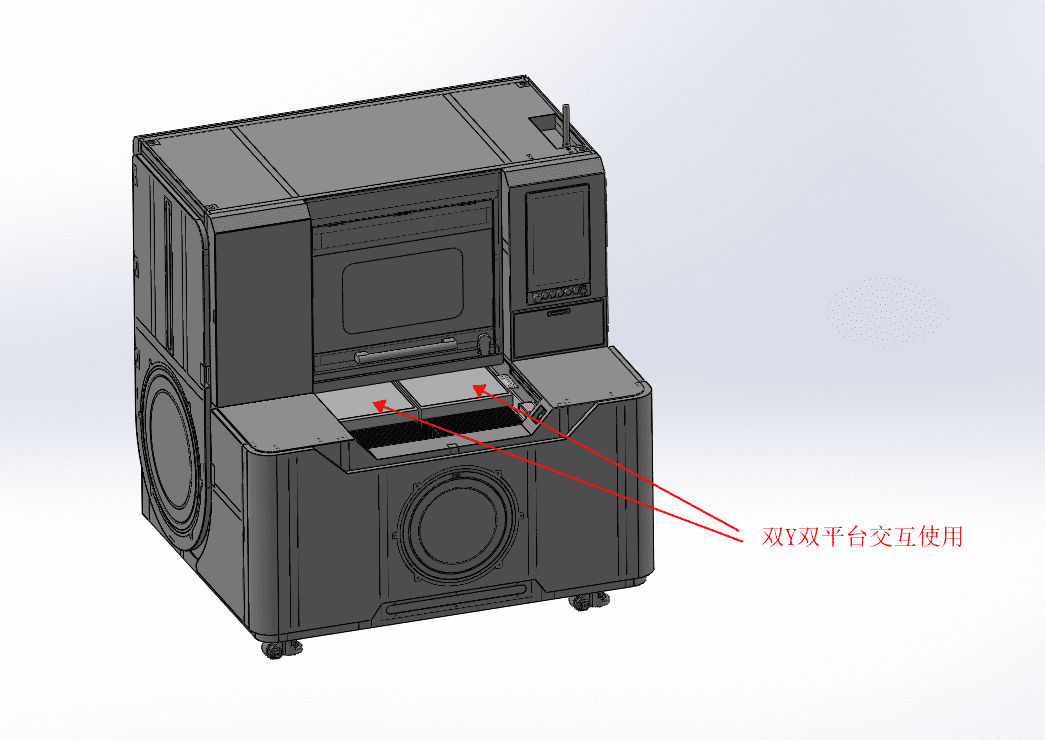

2. Double Y interactive platform, double the cutting efficiency

Working principle of double Y platform: When platform A enters the processing area, it starts cutting, and at the same time, platform B moves to the outside for discharging; after platform A finishes processing, it moves out of the working area, and platform B enters the processing area to start cutting.

“In the process of using a laser cutting machine, the key to improving cutting efficiency is not only the laser head and the laser, but also the interactive platform. As a small branch of the laser cutting machine, the interactive platform is often ignored by many manufacturers, and the company team also Spending a lot of manpower and material resources to carry out innovative research on it, our self-developed and self-produced double-Y interactive platform provides guarantee for the overall cutting efficiency of the cutting machine.” XT LASER picosecond glass cutting machine research and development engineer Bai Gong introduced that double-Y interaction can Save loading and unloading time, realize cycle non-stop cutting, and double the cutting efficiency.

Since the XT infrared picosecond dual-platform glass cutting machine was unveiled at the Guangzhou International Glass Exhibition in August, with its industry-leading infrared picosecond laser technology and the advantages of double Y high-efficiency loading and unloading platforms, it has won awards from more than a dozen cities across the country. Enterprise order. In November, XT picosecond glass cutting products have also been the first to enter the Asia-Pacific region for sales. In order to meet the specific product needs of overseas customers, XT infrared picosecond dual-platform glass cutting models are being upgraded one after another. I believe that XT LASER glass will definitely stand the test of the market, and its products will be spread all over the world.