Laser marking has many good points:

| Key Advantages | Description |

|---|---|

| Traceability | Laser marking provides permanent, tamper-proof IDs on parts, ensuring lifetime traceability. |

| Durability | The markings remain legible even after exposure to harsh conditions, including extreme temperatures. |

| Environmental Resistance | Laser markings resist degradation from chemicals, ensuring identification remains clear throughout service life. |

| Precision | The technology allows for high-precision marks without physical contact, enabling intricate designs. |

| Versatility | It can be used across various materials and integrates seamlessly into automated production lines. |

You can choose from a variety of laser marking styles. Common styles include general marking, annealing, ablation, and deep engraving. General marking is suitable for metals such as steel and aluminum; annealing is ideal for medical components and does not alter the surface condition; ablation exposes the material beneath the surface layer and is suitable for anodized aluminum and painted metals; deep engraving achieves marking depth through 2.5D or 3D laser heads corresponding to the program.

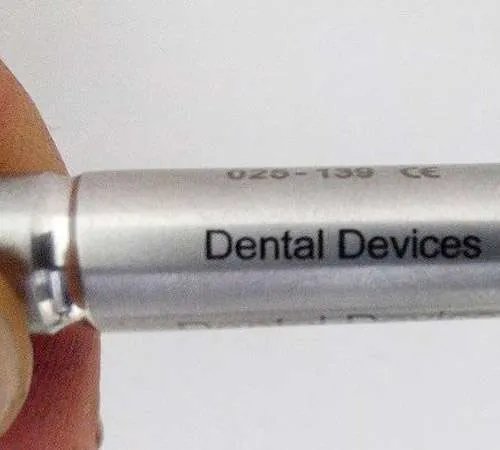

Laser marking helps you follow industry rules. You can use it for cars, planes, medical devices, and electronics. The marks stay readable even after chemicals or heat.

Tip: Laser marking is great if you want fast, accurate, and strong marks on metal parts.