How Does CO2 Compare to Fiber in Terms of Cost?

When comparing CO2 and fiber lasers in terms of cost, here are key factors to consider:

Initial Investment:

Fiber lasers have a higher upfront cost, ranging from $200,000 to $600,000, while CO2 lasers are generally less expensive initially.

Operating Costs:

Fiber lasers are more energy-efficient, costing around $6.24 per hour to operate compared to $12.73 per hour for a CO2 laser, leading to lower long-term operating expenses.

Maintenance:

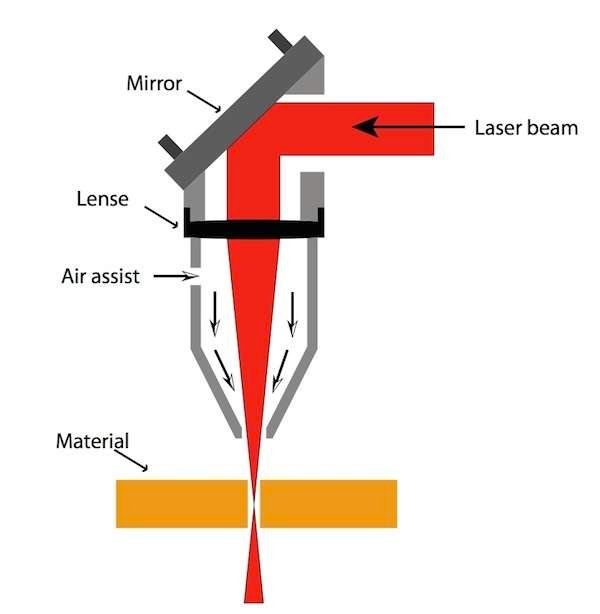

Fiber lasers have fewer moving parts and require less maintenance, while CO2 lasers need more frequent upkeep, including replacing gas tubes and mirrors.

Cutting Speed and Productivity:

Fiber lasers cut up to five times faster, especially on thin materials, increasing productivity and reducing the cost per part.

Lifespan:

Fiber lasers last longer, often up to 25,000 working hours, far surpassing the life of CO2 lasers.

Material Versatility:

CO2 lasers excel with non-metals, while fiber lasers are more versatile and can cut a broader range of materials, including reflective metals.

Long-term Value:

Despite the higher initial cost, fiber lasers often offer better long-term value through higher efficiency, lower operating costs, and greater productivity.