Efficiency

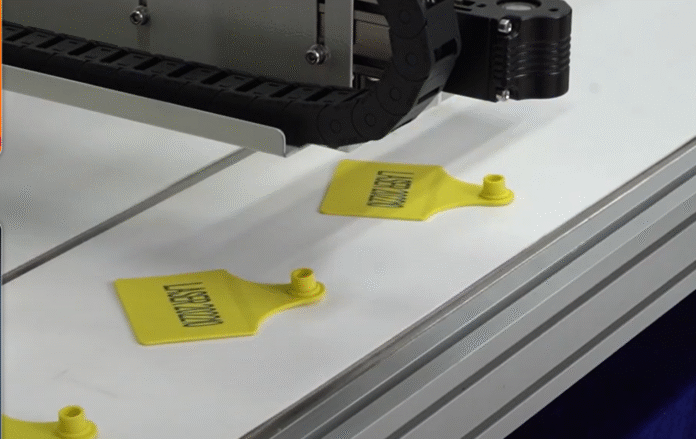

Automated marking equipment helps you work faster. These machines mark products as they move on the line. Flying machines like fiber laser, CO2 laser, and UV laser can mark thousands of items each hour. You do not have to wait long. This means you can make more products in less time.

Traceability

Automated marking equipment lets you track every product from start to end. The marks are clear and last a long time. You can follow each item as it moves through the factory. This is very important for cars and medicine. You can keep track of your products and follow safety rules.

Quality Control

Automated quality control systems check products faster than people.

These systems work all day and night without stopping.

You can find problems early and fix them fast, so you waste less.

Checking every product helps you keep customers happy.

Cost Savings

- Labor Cost Savings: You can save about $44 every hour by using automated systems.

- Increased Throughput: Automated marking equipment can mark 1,500 items each hour, but people can only mark 450.

- Material Waste Reduction: Automation lowers waste from 4% to 0.5%, saving about $630 every hour.