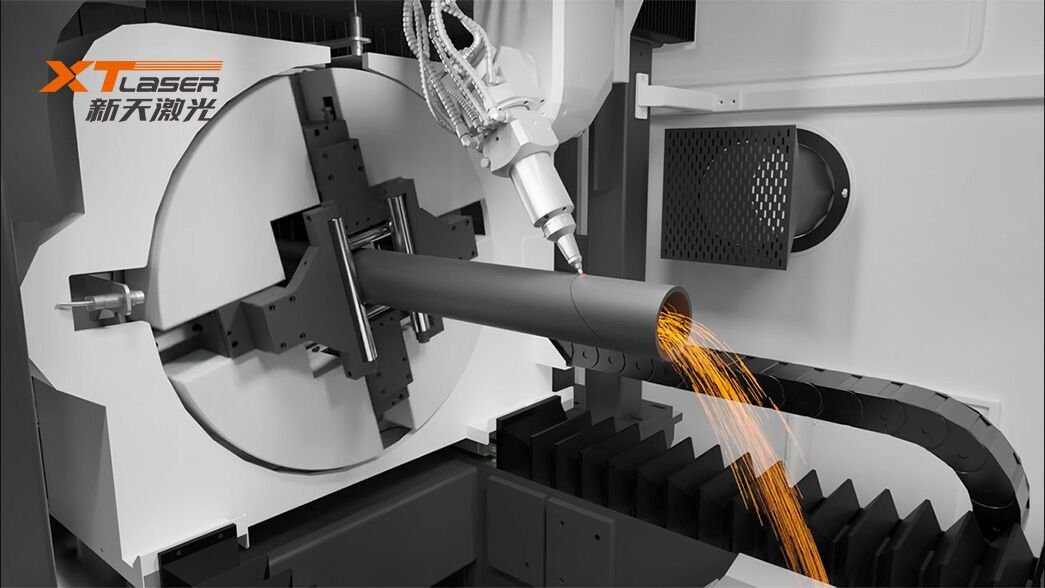

XT Laser-metal laser cutting machine

With the continuous improvement of current laser technology, metal laser cutting machine is also more and more advanced. Previous products such as flame cutting and plasma cutting are not very good in terms of efficiency and accuracy. Processing, so metal laser cutting machine is now very popular, such as metal laser cutting machine for cutting carbon steel, which has the characteristics of good cutting section, high cutting accuracy and fast cutting speed. It is much better than the traditional cutting process. However, because the price of metal laser cutting machine on the market is relatively chaotic, many people directly ask the metal laser cutting machine manufacturer how much they usually quote. In this regard, Xintian Laser will talk about how much metal laser cutting machine manufacturers usually quote.

1. How much is the metal laser cutting machine

Anyone who has bought a metal laser cutting machine knows that the price is calculated according to the configuration. On this basis, if there are special requirements and special processes, the price will rise in different proportions. Generally speaking, the price of a 3000W metal laser cutting machine is hundreds of thousands or even millions. There are also some metal cutting machines with a price of 100000 yuan on the market. This requires consideration of after-sales and quality issues. You get what you pay for

2、 How to calculate the price of metal laser cutting machine.

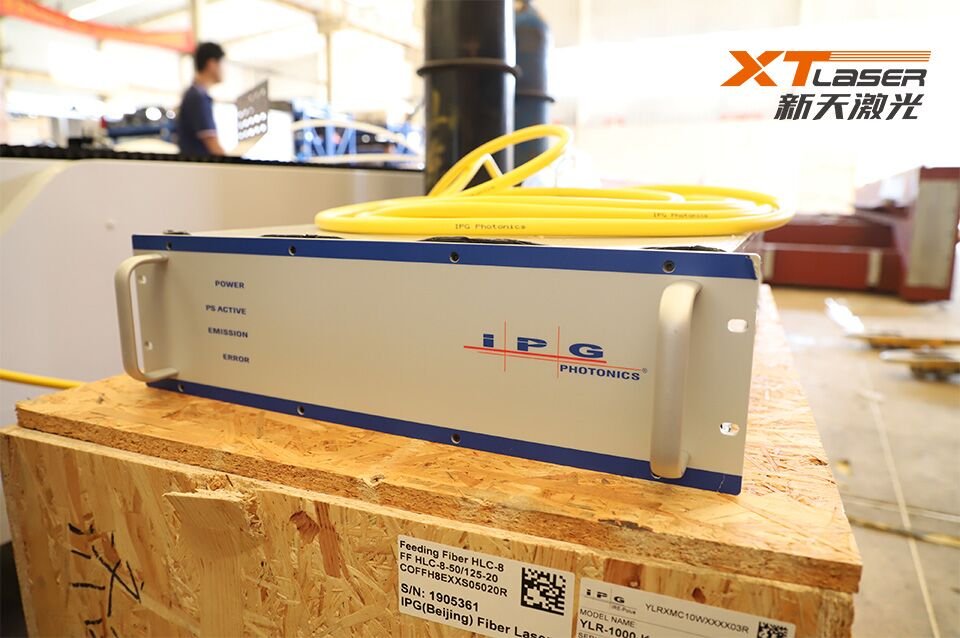

The quotation of fiber laser cutting machine should be based on the materials and processing requirements you process, and whether the laser is domestic or imported, etc. Each manufacturer will have slightly different quotations according to its own technology. At present, the industry classifies fiber laser cutting machines according to their power, mainly including low-power laser cutting machines, medium-power laser cutting machines, and high-power laser cutting machines.

3. Power problem of metal laser cutting machine.

In the market, those below 2000W are called low-power laser cutting machines, and the price is relatively low. 2000W to 80W laser cutting machines are called medium-power laser cutting machines, and their prices tend to be medium. 8000W and above are collectively referred to as high-power laser cutting machines, and the price is also the highest.

In the past few years, the price of domestic laser cutting machine equipment is relatively high, because some of the main parts of the previous equipment rely on imports, and the overall cost is relatively high. However, in recent years, with the enhancement of China’s independent research and development technology capability, the key components of the equipment developed by domestic laser cutting machine manufacturers have matured, and some important components are no longer dependent on imports, so that the price of some large laser cutting machines has been effectively controlled, and domestic manufacturers have gained the trust of the industry.

Fourth, the decisive factor of metal laser cutting machine price.

In fact, the price of metal laser cutting machine depends on the function, power and processing format of the machine. A foreign expert once spoke highly of China’s laser equipment and believed that the increasing number of laser cutting machine companies in China was a sign of progress in the laser industry. However, when various brands are on the market frequently, making today’s promiscuous flowers more and more attractive, how should we choose

1) After-sale service: The laser tube and reflector of the laser cutting machine are consumables with a certain service life and need to be replaced after expiration. This requires the manufacturer to provide strong after-sales service guarantee, so as to provide these consumables in a timely manner. Some users buy laser cutting machines from some small factories at very low prices in order to be cheap. After half a year, the laser cutting machine needs to replace the laser tube. They contacted the manufacturer and found the building empty.

2) Product quality: As the saying goes, the layman watches the bustle while the layman watches the doorway. The same laser cutting machine only uses different parts. The following examples illustrate the differences of several accessories:

a) Stepping motor: it is related to the cutting accuracy of the laser cutting machine. Some manufacturers choose imported stepper motors, some are joint-venture stepper motors, and some are brand-name motors.

b) Laser lens: related to the power of laser cutting machine. There are imported lenses and domestic lenses. Domestic lenses are divided into imported materials and domestic materials. The price gap is large, and the gap between the use effect and the service life is also huge.

C) Laser tube: This is the heart of laser cutting machine. Due to the high price of imported laser tubes, which are generally around tens of thousands of yuan, most of the laser tubes used by domestic laser cutting machines are also domestic. The price of domestic laser tubes also varies greatly.

The service life of a good laser tube is generally about 3000 hours.

Mechanical assembly quality: In order to reduce costs, some manufacturers use very thin iron sheets to manufacture the casing. Generally, users can’t see it, but over time, the frame will be deformed, which will affect the cutting accuracy of the laser cutting machine.

A good laser cutting machine should be of frame structure, welded with high-quality steel, and made of high-quality cold-rolled steel plate. When purchasing the machine, users can check whether the frame structure of the machine casing is used, the thickness and strength of the iron sheet of the machine casing, etc. to understand the quality.

3) Some people familiar with laser cutting machines lament that the configuration of laser cutting machines has increased so much now, but the price has decreased compared with previous years. How gratifying.

But some people immediately said that don’t be confused by those bright external things. Compared with the convenience and efficiency of reliability and maintenance services, many new equipment are not as good as the “old three” in previous years. The author believes that users should pay more attention to the cost performance of laser cutting machines. The laser cutting machine with “medium configuration and moderate price” is our best choice.

Many users have fallen into a misunderstanding and hope that the laser cutting machine they buy is “all-powerful” and omnipotent, which is actually a big misunderstanding.

The above is a comprehensive introduction about the cost of metal laser cutting machine by Xintian Laser. If you want to know more, please pay attention to Xintian Laser and contact us online.