Introduction: Is Your Factory “Marketing Clean” or “Real World Clean”?

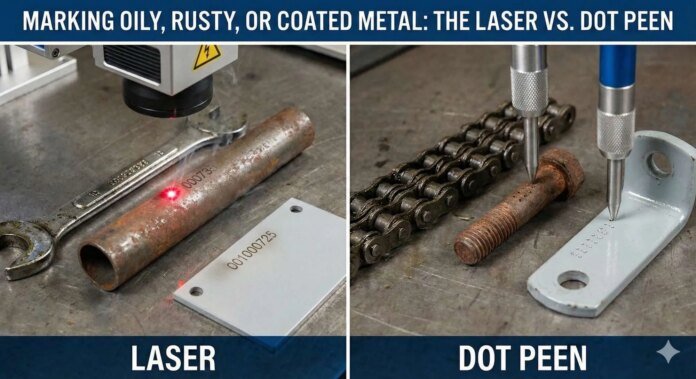

Browse most marking machine catalogs, and you will see a pleasant sight: pristine stainless steel, spotless aluminum, and lab-quality conditions.

But on the factory floor, reality is different.

As a manager in a foundry, heat treatment shop, or automotive remanufacturing plant, you are dealing with:

- Gears dripping with quenching oil.

- Cast iron parts covered in scale and rust.

- Machined components coated in cutting fluid and metal dust.

The question we hear most often is: “Do I have to wash these parts before marking them?”

If your answer is “No, I don’t have time to wash them,” then this guide is for you. Today, HeatSign is dropping the marketing filter to give you an honest comparison of Fiber Laser vs. Dot Peen in harsh industrial environments.