Initial Assessment and Choosing the Right Method:

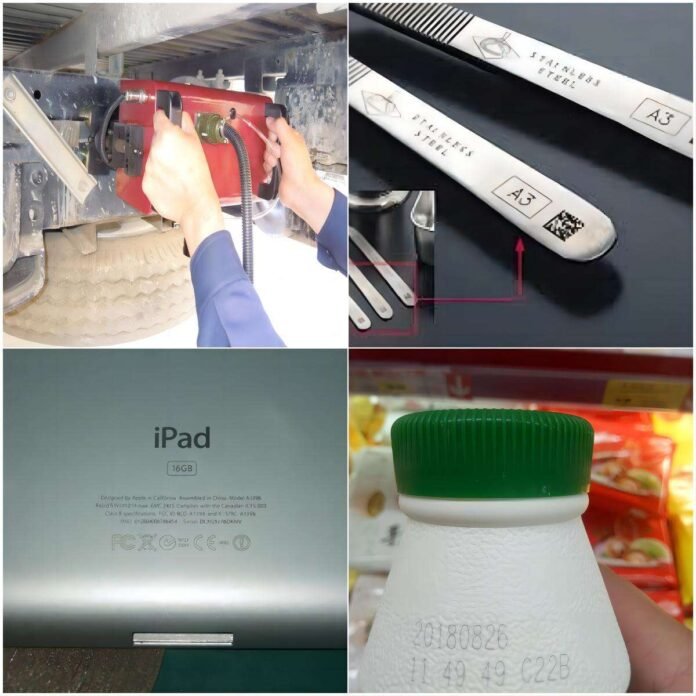

Assess the specific requirements of the parts, including material, size, shape, and the information to be marked. Choose the most suitable method—laser marking, dot peen marking, inkjet printing, RFID tagging, or barcode labeling—based on durability, precision, and cost.

Setting Up the Marking Equipment:

Configure the marking equipment to the specifications required for the parts. Adjust settings such as laser intensity, speed, and focus for laser markers, or stylus pressure and pattern for dot peen markers. Proper setup ensures consistent and high-quality marks.

Testing and Validation:

Conduct thorough testing and validation before full-scale production. Mark sample parts and inspect for quality and accuracy. Make necessary adjustments to the equipment settings to ensure marks meet required standards for readability and durability.

Integration with Production Lines:

Integrate the marking process with existing production lines for efficiency. Synchronize marking equipment with other manufacturing processes to ensure smooth operation. Automation and robotics can streamline the process, reduce manual handling, and increase throughput.